| Example: | Wilo-COR-1 MVIE 7002 / GE |

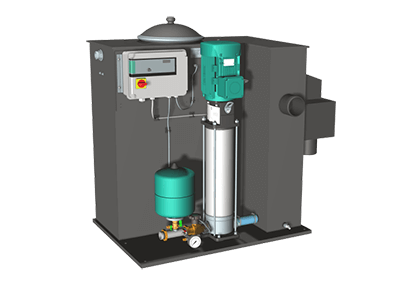

| CO | Compact pressure boosting system |

| R | Regulation with a frequency converter |

| 1 | Single pump |

| MVIE | Pump Series |

| 70 | Nominal volumetric flow of a single pump (m 3 / h) |

| 02 | Number of stages of a single pump |

| GE | Main unit, without control device |

Connection-ready water-supply unit with vertically arranged, normally aspirated MVIE 70 or 95 series centrifugal pumps, with integrated, air-cooled frequency converter.

| Product designation | Network connection | Number of pumps | Number of standby pumps | Maximum working pressure PN | Gross weight approx. m | Article number |

|---|---|---|---|---|---|---|

| COR-1MVIE7002-GE | 3~380 V, 50/60 Hz | 1 | 0 | 16 bar | 384.0 kg | 2551690 |

| COR-1MVIE7003/1-GE | 3~380 V, 50/60 Hz | 1 | 0 | 16 bar | 384.0 kg | 2551691 |

| COR-1MVIE7004/2-GE | 3~380 V, 50/60 Hz | 1 | 0 | 16 bar | 445.0 kg | 2551692 |

| COR-1MVIE7004-GE | 3~380 V, 50/60 Hz | 1 | 0 | 16 bar | 445.0 kg | 2551693 |

| COR-1MVIE9501-GE | 3~380 V, 50/60 Hz | 1 | 0 | 16 bar | 380.0 kg | 2551694 |

| COR-1MVIE9502/1-GE | 3~380 V, 50/60 Hz | 1 | 0 | 16 bar | 382.0 kg | 2551695 |

| COR-1MVIE9502-GE | 3~380 V, 50/60 Hz | 1 | 0 | 16 bar | 439.0 kg | 2551696 |

| COR-1MVIE7003/2-GE | 3~380 V, 50/60 Hz | 1 | 0 | 16 bar | 443.0 kg | 2551697 |

Foundation frame: Made of galvanized steel, with height-adjustable anti-vibration mounts, ensuring good structure-borne sound insulation, as well as integrated rigging points.

Piping: On the pressure side there is a complete stainless steel piping system, suitable for connection of all materials used in building services equipment; the piping is designed in accordance with the total hydraulic capacity of the pressure boosting unit.

Pumps: One MVIE 70 and MVIE 95 series pump each.

Air-cooled frequency converters on the pump motor provide infinitely variable speed control between 25 Hz and a maximum of 60 Hz for all pumps of these series. 60 Hz. All pump parts in contact with the pumped liquid are made of stainless steel/grey cast iron with cataphoresis coating and ACS approval (see section "Material description").

Fittings: On the pressure side the pump is equipped with a ball shut-off valve with DVGW approval mark or a ring gate valve and a non-return valve with DVGW approval.

Diaphragm pressure vessel 8 l/PN 16 located on the discharge side, with a butyl rubber diaphragm, DVGW/KTW approval, compliant with food safety laws, equipped with a shut-off ball cock for inspection and testing purposes, with a drainage system and flow fittings with DVGW/KTW approval to DIN 4807.

Pressure monitoring: 2 pressure sensors 4 ... 20 mA, arranged on suction and pressure side.

Pressure display: Pressure gauge located on the suction and final pressure sides.

Other versions on request

The Wilo CAD online library contains DWG drawings of Wilo pumping equipment. In this library, the dimensions of the pumping equipment are given as a guideline. Please note that the contents of the Wilo CAD online library are subject to technical changes.

We will tell you in detail about our services, types of work and typical projects, calculate the cost and prepare an individual offer!