| Example: | Wilo-COR / T-1 Helix VE 403 |

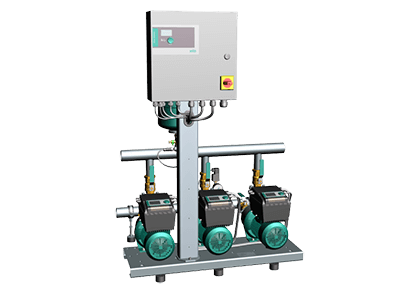

| COR | Compact booster system with integrated speed control |

| T | With integrated storage tank as system separator |

| 1 | Single pump |

| Helix VE | Series of pumps with integrated speed control |

| 4 | Nominal volume flow of single pump [m 3 /h] |

| 03 | Number of single pump sections |

Water supply unit with system separator and speed-controlled standard-suction high-pressure multistage centrifugal pump

| Product designation | Mains connection | Maximum working pressure PN | Number of pumps | Number of standby pumps | Power output without standby pumpQ | Gross weight approx. m | Article number |

|---|---|---|---|---|---|---|---|

| COR/T-1 Helix VE403-GE | 3~400 V, 50 Hz | 16 bar | 1 | 0 | 8.0 m³/h | 123.0 kg | 2547961 |

| COR/T-1 Helix VE404-GE | 3~400 V, 50 Hz | 16 bar | 1 | 0 | 8.0 m³/h | 126.0 kg | 2547962 |

| COR/T-1 Helix VE405-GE | 3~400 V, 50 Hz | 16 bar | 1 | 0 | 8.0 m³/h | 128.0 kg | 2547963 |

| COR/T-1 Helix VE407-GE | 3~400 V, 50 Hz | 16 bar | 1 | 0 | 8.0 m³/h | 136.0 kg | 2547964 |

| COR/T-1 Helix VE410-GE | 3~400 V, 50 Hz | 16 bar | 1 | 0 | 8.0 m³/h | 138.0 kg | 2547965 |

| COR/T-1 Helix VE413-GE | 3~400 V, 50 Hz | 16 bar | 1 | 0 | 8.0 m³/h | 147.0 kg | 2547966 |

| COR/T-1 Helix VE602-GE | 3~400 V, 50 Hz | 16 bar | 1 | 0 | 12.0 m³/h | 126.0 kg | 2547967 |

| COR/T-1 Helix VE603-GE | 3~400 V, 50 Hz | 16 bar | 1 | 0 | 12.0 m³/h | 128.0 kg | 2547968 |

| COR/T-1 Helix VE604-GE | 3~400 V, 50 Hz | 16 bar | 1 | 0 | 12.0 m³/h | 135.0 kg | 2547969 |

| COR/T-1 Helix VE606-GE | 3~400 V, 50 Hz | 16 bar | 1 | 0 | 12.0 m³/h | 137.0 kg | 2547970 |

| COR/T-1 Helix VE608-GE | 3~400 V, 50 Hz | 16 bar | 1 | 0 | 12.0 m³/h | 147.0 kg | 2547971 |

| COR/T-1 Helix VE611-GE | 3~400 V, 50 Hz | 16 bar | 1 | 0 | 12.0 m³/h | 158.0 kg | 2547972 |

Connection-ready water-supply unit, mounted on a polyethylene base frame, complete piping system including all necessary fittings and shut-off devices (except for inlet-side shut-off devices), pressure sensor set, stainless steel high-pressure multistage centrifugal pump in glanded version with integrated frequency converter (Helix VE series)

Diaphragm pressure vessel 8 l/PN 16 located on the discharge side with a butyl rubber diaphragm in accordance with food safety laws; with isolation device for inspection and testing purposes, with emptying system and flow-through device in accordance with DIN 4807

The Wilo CAD online library contains DWG drawings of Wilo pumping equipment. In this library, the dimensions of the pumping equipment are given as a guideline. Please note that the contents of the Wilo CAD online library are subject to technical changes.

We will tell you in detail about our services, types of work and typical projects, calculate the cost and prepare an individual offer!