| Example: | Wilo- FLA – 2 Helix V 2204 PN10 |

| FLA | Fire extinguishing installations |

| 2 | Number of pumps |

| Helix V | Pump Series |

| 22 | Nominal flow [m 3 / h] |

| 04 | Number of pump sections |

| PN10 | Pressure regulation range: up to 10 bar (depending on pump type) |

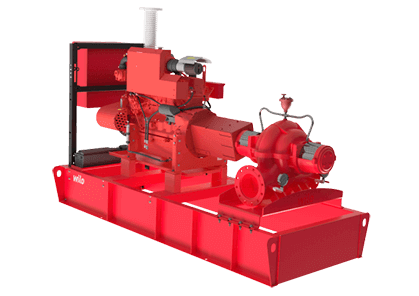

Reliable unit with 2 high-pressure stainless steel Helix FIRST V or MVI centrifugal pumps, compliant with DIN 1988 and DIN 14462

Absolute reliability in dual-pump operation through 100% redundancy

Simple set-up and reliable operation thanks to FLA control

Pre-adjusted throttle valve on the discharge side of the pump ensures pump protection at low flow rates

Pressure booster set for direct-coupled firefighting units according to DIN 14462.

With two vertical stainless steel high-pressure multistage centrifugal pumps with dry rotor

Automated water supply system for fire-fighting installations with type "F" wall-mounted hydrants in residential, industrial and public buildings, hotels, hospitals, shopping centers and office and industrial buildings

Equipment/function

| Product designation | Unit capacity without standby pump Q | Gross weight approx. m | Maximum working pressure PN | Number of pumps | Number of standby pumps | Article number |

|---|---|---|---|---|---|---|

| FLA-2 Helix V 1604 PN10 | 18.0 m³/h | 246.0 kg | 10 bar | 2 | 1 | 2534358 |

| FLA-2 Helix V 1605 PN10 | 18.0 m³/h | 272.0 kg | 10 bar | 2 | 1 | 2534359 |

| FLA-2 Helix V 1606 PN10 | 18.0 m³/h | 274.0 kg | 10 bar | 2 | 1 | 2534360 |

| FLA-2 Helix V 1607 PN10 | 18.0 m³/h | 360.0 kg | 10 bar | 2 | 1 | 2534361 |

| FLA-2 Helix V 1608 PN16 | 18.0 m³/h | 365.0 kg | 16 bar | 2 | 1 | 2534362 |

| FLA-2 Helix V 1609 PN16 | 18.0 m³/h | 417.0 kg | 16 bar | 2 | 1 | 2534363 |

| FLA-2 Helix V 1610 PN16 | 18.0 m³/h | 421.0 kg | 16 bar | 2 | 1 | 2534364 |

| FLA-2 Helix V 1611 PN16 | 18.0 m³/h | 424.0 kg | 16 bar | 2 | 1 | 2534365 |

| FLA-2 Helix V 1612 PN16 | 18.0 m³/h | 597.0 kg | 16 bar | 2 | 1 | 2534366 |

| FLA-2 Helix V 3602/1 PN10 | 36.0 m³/h | 437.0 kg | 10 bar | 2 | 1 | 2534380 |

| FLA-2 Helix V 3602 PN10 | 36.0 m³/h | 437.0 kg | 10 bar | 2 | 1 | 2534381 |

| FLA-2 Helix V 3603/2 PN10 | 36.0 m³/h | 440.0 kg | 10 bar | 2 | 1 | 2534382 |

| FLA-2 Helix V 3603/1 PN10 | 36.0 m³/h | 440.0 kg | 10 bar | 2 | 1 | 2534383 |

| FLA-2 Helix V 3603 PN10 | 36.0 m³/h | 450.0 kg | 10 bar | 2 | 1 | 2534384 |

| FLA-2 Helix V 3604/2 PN10 | 36.0 m³/h | 475.0 kg | 10 bar | 2 | 1 | 2534385 |

| FLA-2 Helix V 3604 PN16 | 36.0 m³/h | 475.0 kg | 16 bar | 2 | 1 | 2534386 |

| FLA-2 Helix V 3605/2 PN16 | 36.0 m³/h | 635.0 kg | 16 bar | 2 | 1 | 2534387 |

| FLA-2 Helix V 3605 PN16 | 36.0 m³/h | 635.0 kg | 16 bar | 2 | 1 | 2534388 |

| FLA-2 Helix V 3606/2 PN16 | 36.0 m³/h | 657.0 kg | 16 bar | 2 | 1 | 2534389 |

| FLA-2 Helix V 3606 PN16 | 36.0 m³/h | 670.0 kg | 16 bar | 2 | 1 | 2534390 |

| FLA-2 Helix V 5202 PN10 | 48.0 m³/h | 503.0 kg | 10 bar | 2 | 1 | 2534401 |

| FLA-2 Helix V 5203/2 PN10 | 48.0 m³/h | 545.0 kg | 10 bar | 2 | 1 | 2534402 |

| FLA-2 Helix V 5203 PN10 | 48.0 m³/h | 545.0 kg | 10 bar | 2 | 1 | 2534403 |

| FLA-2 Helix V 5204/2 PN10 | 48.0 m³/h | 696.0 kg | 10 bar | 2 | 1 | 2534404 |

| FLA-2 Helix V 5204 PN16 | 48.0 m³/h | 696.0 kg | 16 bar | 2 | 1 | 2534405 |

| FLA-2 Helix V 5205/2 PN16 | 48.0 m³/h | 719.0 kg | 16 bar | 2 | 1 | 2534406 |

| FLA-2 Helix V 5205 PN16 | 48.0 m³/h | 719.0 kg | 16 bar | 2 | 1 | 2534407 |

| FLA-2 Helix V 5206/2 PN16 | 48.0 m³/h | 735.0 kg | 16 bar | 2 | 1 | 2534408 |

| FLA-2 Helix V 2204 PN10 | 24.0 m³/h | 601.0 kg | 10 bar | 2 | 1 | 2534433 |

| FLA-2 Helix V 2205 PN10 | 24.0 m³/h | 623.0 kg | 10 bar | 2 | 1 | 2534434 |

| FLA-2 Helix V 2206 PN16 | 24.0 m³/h | 627.0 kg | 16 bar | 2 | 1 | 2534435 |

| FLA-2 Helix V 2207 PN16 | 24.0 m³/h | 648.0 kg | 16 bar | 2 | 1 | 2534436 |

| FLA-2 Helix V 2208 PN16 | 24.0 m³/h | 728.0 kg | 16 bar | 2 | 1 | 2534437 |

| FLA-2 MVI 7002/1 PN10 | 48.0 m³/h | 841.0 kg | 10 bar | 2 | 1 | 2536590 |

| FLA-2 MVI 7002 PN10 | 48.0 m³/h | 842.0 kg | 10 bar | 2 | 1 | 2536591 |

| FLA-2 MVI 7003/2 PN10 | 48.0 m³/h | 923.0 kg | 10 bar | 2 | 1 | 2536592 |

| FLA-2 MVI 7003/1 PN10 | 48.0 m³/h | 923.0 kg | 10 bar | 2 | 1 | 2536593 |

| FLA-2 MVI 7003 PN10 | 48.0 m³/h | 989.0 kg | 10 bar | 2 | 1 | 2536594 |

| FLA-2 MVI 7004/2 PN10 | 48.0 m³/h | 997.0 kg | 10 bar | 2 | 1 | 2536595 |

| FLA-2 MVI 7004/1 PN16 | 48.0 m³/h | 1072.0 kg | 16 bar | 2 | 1 | 2536596 |

| FLA-2 MVI 7004 PN16 | 48.0 m³/h | 836.0 kg | 16 bar | 2 | 1 | 2536597 |

| FLA-2 MVI 7005/2 PN16 | 48.0 m³/h | 1323.0 kg | 16 bar | 2 | 1 | 2536598 |

| FLA-2 MVI 7005/1 PN16 | 48.0 m³/h | 1323.0 kg | 16 bar | 2 | 1 | 2536599 |

| FLA-2 MVI 7005 PN16 | 48.0 m³/h | 1323.0 kg | 16 bar | 2 | 1 | 2536600 |

| FLA-2 MVI 7006/2 PN16 | 48.0 m³/h | 1397.0 kg | 16 bar | 2 | 1 | 2536601 |

| FLA-2 MVI 7006/1 PN16 | 48.0 m³/h | 1448.0 kg | 16 bar | 2 | 1 | 2536602 |

The Wilo CAD online library contains DWG drawings of Wilo pumping equipment. In this library, the dimensions of the pumping equipment are given as a guideline. Please note that the contents of the Wilo CAD online library are subject to technical changes.

We will tell you in detail about our services, types of work and typical projects, calculate the cost and prepare an individual offer!