| Example: | Wilo-SiFire Easy 40/200-180-7.5/10.5 EDJ |

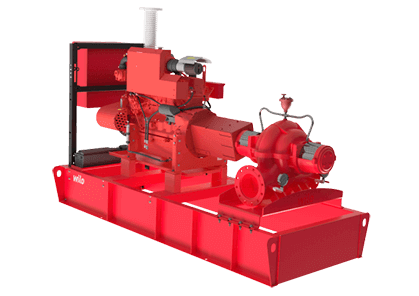

| SiFire | Compact pressure booster for fire extinguishing systems |

| Easy | Easy to use and complies with EN 12845 |

| 40/200 | Main pump type |

| 180 | Fact. main pump impeller diameter |

| 7.5 | Motor power [kW] |

| 10.5 | Diesel engine power [kW] |

| EDJ | Selection |

| E | Electric pump |

| D | Diesel pump |

| J | Jockey Pump |

Automatic water supply system for fire sprinkler systems in residential, office and administrative buildings, hotels, hospitals, shopping centers and industrial buildings.

| Product designation | Unit capacity without standby pump Q | Gross weight approx. m | Maximum working pressure PN | Number of pumps | Number of standby pumps | Article number |

|---|---|---|---|---|---|---|

| SiFire-Easy-32/200-154-4E | 29.0 m³/h | 475.0 kg | 16 bar | - | - | 4241981 |

| SiFire-Easy-32/200-172-5,5E | 34.0 m³/h | 497.0 kg | 16 bar | - | - | 4241982 |

| SiFire-Easy-32/200-182-7,5E | 36.0 m³/h | 500.0 kg | 16 bar | - | - | 4241983 |

| SiFire-Easy-32/200-191-7,5E | 37.0 m³/h | 500.0 kg | 16 bar | - | - | 4241984 |

| SiFire-Easy-32/200-200-11E | 39.0 m³/h | 582.0 kg | 16 bar | - | - | 4241985 |

| SiFire-Easy-32/250-198-7,5E | 31.0 m³/h | 594.0 kg | 16 bar | - | - | 4241986 |

| SiFire-Easy-32/250-222-11E | 34.0 m³/h | 594.0 kg | 16 bar | - | - | 4241987 |

| SiFire-Easy-32/250-234-15E | 35.0 m³/h | 634.0 kg | 16 bar | 1 | - | 4241988 |

| SiFire-Easy-32/250-246-15E | 37.0 m³/h | 766.0 kg | 16 bar | - | - | 4241989 |

| SiFire-Easy-32/250-262-18,5E | 39.0 m³/h | 502.0 kg | 16 bar | - | 0 | 4241990 |

| SiFire-Easy-40/200-188-7,5E | 53.0 m³/h | 568.0 kg | 16 bar | - | - | 4241991 |

| SiFire-Easy-40/200-205-11E | 62.0 m³/h | 568.0 kg | 16 bar | - | - | 4241992 |

| SiFire-Easy-40/200-212-15E | 66.0 m³/h | 568.0 kg | 16 bar | - | - | 4241993 |

| SiFire-Easy-40/250-218-15E | 55.0 m³/h | 576.0 kg | 16 bar | 1 | - | 4241994 |

| SiFire-Easy-40/250-226-18,5E | 59.0 m³/h | 576.0 kg | 16 bar | 1 | - | 4241995 |

| SiFire-Easy-40/250-244-22E | 61.0 m³/h | 577.0 kg | 16 bar | - | - | 4241996 |

| SiFire-Easy-40/250-250-30E | 61.0 m³/h | 585.0 kg | 16 bar | - | - | 4241997 |

| SiFire-Easy-50/160-147-5,5E | 81.0 m³/h | 585.0 kg | 16 bar | - | - | 4241998 |

| SiFire-Easy-50/160-155-7,5E | 81.0 m³/h | 585.0 kg | 16 bar | - | - | 4241999 |

| SiFire-Easy-50/160-173-11E | 78.0 m³/h | 597.0 kg | 16 bar | - | - | 4242000 |

| SiFire-Easy-50/160-178-15E | 81.0 m³/h | 597.0 kg | 16 bar | - | 0 | 4242001 |

| SiFire-Easy-50/200-182-11E | 86.0 m³/h | 637.0 kg | 16 bar | 1 | 0 | 4242002 |

| SiFire-Easy-50/200-192-15E | 88.0 m³/h | 637.0 kg | 16 bar | 1 | 0 | 4242003 |

| SiFire-Easy-50/200-202-15E | 83.0 m³/h | 505.0 kg | 16 bar | - | - | 4242004 |

| SiFire-Easy-50/200-210-18,5E | 84.0 m³/h | 505.0 kg | 16 bar | 1 | - | 4242005 |

| SiFire-Easy-50/200-218-22E | 86.0 m³/h | 571.0 kg | 16 bar | 1 | - | 4242006 |

| SiFire-Easy-50/250-220-18,5E | 83.0 m³/h | 577.0 kg | 16 bar | - | - | 4242007 |

| SiFire-Easy-50/250-240-22E | 79.0 m³/h | 577.0 kg | 16 bar | - | 0 | 4242008 |

| SiFire-Easy-50/250-242-30E | 81.0 m³/h | 585.0 kg | 16 bar | - | - | 4242009 |

| SiFire-Easy-50/250-249-30E | 83.0 m³/h | 585.0 kg | 16 bar | 1 | 0 | 4242010 |

| SiFire-Easy-50/250-258-37E | 85.0 m³/h | 807.0 kg | 16 bar | 1 | 0 | 4242011 |

| SiFire-Easy-65/200-178-15E | 137.0 m³/h | 597.0 kg | 16 bar | 1 | 0 | 4242012 |

| SiFire-Easy-65/200-185-18,5E | 125.0 m³/h | 637.0 kg | 16 bar | 1 | 0 | 4242013 |

| SiFire-Easy-65/200-195-22E | 128.0 m³/h | 644.0 kg | 16 bar | 1 | 0 | 4242014 |

| SiFire-Easy-65/200-207-30E | 133.0 m³/h | 776.0 kg | 16 bar | 1 | 0 | 4242015 |

| SiFire-Easy-65/200-214-30E | 135.0 m³/h | 776.0 kg | 16 bar | 1 | 0 | 4242016 |

| SiFire-Easy-65/200-226-37E | 138.0 m³/h | 607.0 kg | 16 bar | 1 | 0 | 4242017 |

| SiFire-Easy-65/250-226-30E | 141.0 m³/h | 647.0 kg | 16 bar | 1 | 0 | 4242018 |

| SiFire-Easy-65/250-248-37E | 111.0 m³/h | 647.0 kg | 16 bar | 1 | 0 | 4242019 |

| SiFire-Easy-65/250-258-45E | 113.0 m³/h | 779.0 kg | 16 bar | 1 | 0 | 4242020 |

| SiFire-Easy-65/250-264-55E | 114.0 m³/h | 806.0 kg | 16 bar | 1 | 0 | 4242021 |

| SiFire-Easy-65/315-295-75E | 124.0 m³/h | 845.0 kg | 16 bar | 1 | 0 | 4242022 |

| SiFire-Easy-65/315-305-75E | 125.0 m³/h | 946.0 kg | 16 bar | - | - | 4242023 |

| SiFire-Easy-65/315-316-90E | 125.0 m³/h | 1003.0 kg | 16 bar | 1 | 0 | 4242024 |

| SiFire-Easy-65/315-330-110E | 125.0 m³/h | 1328.0 kg | 16 bar | 1 | 0 | 4242025 |

| SiFire-Easy-80/200-185-22E | 179.0 m³/h | 805.0 kg | 16 bar | 1 | 0 | 4242026 |

| SiFire-Easy-80/200-195-30E | 188.0 m³/h | 805.0 kg | 16 bar | 1 | 0 | 4242027 |

| SiFire-Easy-80/200-201-30E | 191.0 m³/h | 844.0 kg | 16 bar | 1 | 0 | 4242028 |

| SiFire-Easy-80/200-210-37E | 195.0 m³/h | 945.0 kg | 16 bar | 1 | 0 | 4242029 |

| SiFire-Easy-80/200-224-45E | 200.0 m³/h | 1014.0 kg | 16 bar | 1 | 0 | 4242030 |

| SiFire-Easy-80/200-228-55E | 202.0 m³/h | 1337.0 kg | 16 bar | - | - | 4242031 |

| SiFire-Easy-80/250-235-55E | 227.0 m³/h | 1337.0 kg | 16 bar | 1 | 0 | 4242032 |

| SiFire-Easy-80/250-243-75E | 233.0 m³/h | 1376.0 kg | 16 bar | 1 | 0 | 4242033 |

| SiFire-Easy-80/250-254-75E | 232.0 m³/h | 1588.0 kg | 16 bar | 1 | 0 | 4242034 |

| SiFire-Easy-80/250-270-90E | 232.0 m³/h | 1624.0 kg | 16 bar | 1 | 0 | 4242035 |

| SiFire-Easy-80/315-275-90E | 225.0 m³/h | 1337.0 kg | 16 bar | 1 | 0 | 4242036 |

| SiFire-Easy-80/315-290-110E | 216.0 m³/h | 1337.0 kg | 16 bar | 1 | 0 | 4242037 |

| SiFire-Easy-80/315-308-132E | 219.0 m³/h | 1376.0 kg | 16 bar | 1 | 0 | 4242038 |

| SiFire-Easy-80/315-318-160E | 221.0 m³/h | 1588.0 kg | 16 bar | - | - | 4242039 |

| SiFire-Easy-80/315-324-160E | 223.0 m³/h | 1624.0 kg | 16 bar | 1 | 0 | 4242040 |

| SiFire-Easy-100/200-212-45E | 250.0 m³/h | 1624.0 kg | 16 bar | 1 | 0 | 4242041 |

| SiFire-Easy-100/200-222-55E | 323.0 m³/h | 1382.0 kg | 16 bar | 1 | 0 | 4242042 |

| SiFire-Easy-100/200-228-75E | 321.0 m³/h | 1421.0 kg | 16 bar | 1 | 0 | 4242043 |

| SiFire-Easy-100/250-255-90E | 276.0 m³/h | 1615.0 kg | 16 bar | - | - | 4242044 |

| SiFire-Easy-100/250-260-110E | 273.0 m³/h | 1665.0 kg | 16 bar | 1 | 0 | 4242045 |

| SiFire-Easy-100/250-267-110E | 273.0 m³/h | 1746.0 kg | 16 bar | 1 | 0 | 4242046 |

| SiFire-Easy-100/250-280-132E | 273.0 m³/h | 1466.0 kg | 16 bar | 1 | 0 | 4242047 |

| SiFire-Easy-100/315-285-132E | 421.0 m³/h | 1660.0 kg | 16 bar | - | - | 4242048 |

| SiFire-Easy-100/315-296-160E | 345.0 m³/h | 1696.0 kg | 16 bar | 1 | 0 | 4242049 |

| SiFire-Easy-100/315-302-160E | 349.0 m³/h | 1777.0 kg | 16 bar | 1 | 0 | 4242050 |

| SiFire-Easy-100/315-318-200E | 360.0 m³/h | 1824.0 kg | 16 bar | 1 | 0 | 4242051 |

| SiFire-Easy-125/250-266-160E | 499.0 m³/h | 2315.0 kg | 16 bar | 1 | 0 | 4242054 |

| SiFire-Easy-125/250-274-200E | 507.0 m³/h | 2315.0 kg | 16 bar | 1 | 0 | 4242055 |

| SiFire-Easy-32/200-154-4,2D | 29.0 m³/h | 570.0 kg | 16 bar | 1 | 0 | 4242131 |

| SiFire-Easy-32/200-172-6,8D | 34.0 m³/h | 585.0 kg | 16 bar | 1 | 0 | 4242132 |

| SiFire-Easy-32/200-182-6,8D | 36.0 m³/h | 585.0 kg | 16 bar | 1 | 0 | 4242133 |

| SiFire-Easy-32/200-191-10,5D | 37.0 m³/h | 615.0 kg | 16 bar | 1 | 0 | 4242134 |

| SiFire-Easy-32/200-200-10,5D | 39.0 m³/h | 675.0 kg | 16 bar | 1 | 0 | 4242135 |

| SiFire-Easy-32/250-198-6,8D | 31.0 m³/h | 675.0 kg | 16 bar | 1 | 0 | 4242136 |

| SiFire-Easy-32/250-222-10,5D | 34.0 m³/h | 730.0 kg | 16 bar | 1 | 0 | 4242137 |

| SiFire-Easy-32/250-234-12,9D | 35.0 m³/h | 730.0 kg | 16 bar | 1 | 0 | 4242138 |

| SiFire-Easy-32/250-246-17,7D | 37.0 m³/h | 565.0 kg | 16 bar | 1 | 0 | 4242139 |

| SiFire-Easy-32/250-262-17,7D | 39.0 m³/h | 617.0 kg | 16 bar | 1 | 0 | 4242140 |

| SiFire-Easy-40/200-188-6,8D | 53.0 m³/h | 617.0 kg | 16 bar | 1 | 0 | 4242141 |

| Example: | Wilo-SiFire Easy 40 / 200-180-7.5 / 10.5 EDJ |

| SiFire | Compact pressure boosting system for fire extinguishing systems |

| Easy | Easy to use and compliant with EN 12845 |

| 40/200 | Main pump type |

| 180 | Fact. main pump impeller diameter |

| 7.5 | Motor power [kW] |

| 10.5 | Diesel engine power [kW] |

| EDJ | Selection |

| E | Electric pump |

| D | Diesel Pump |

| J | Jockey Pump |

The Wilo CAD online library contains DWG drawings of Wilo pumping equipment. In this library, the dimensions of the pumping equipment are given as a guideline. Please note that the contents of the Wilo CAD online library are subject to technical changes.

We will tell you in detail about our services, types of work and typical projects, calculate the cost and prepare an individual offer!