| Example: | Wilo-SiBoost Smart 1 Helix VE 2204-ES |

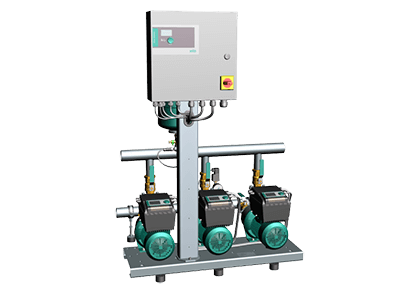

| SiBoost Smart | Compact booster system with integrated speed control |

| 1 | Number of pumps |

| Helix VE | Pump Series |

| 22 | Nominal volumetric flow [m3/h] single pump |

| 04 | Number of single pump sections |

| ES | Stainless steel version 22 .., 36 .., 52 .. |

High-efficiency connection-ready water supply unit with vertically arranged, normally aspirated high-output Helix VE series centrifugal pump with integrated, air-cooled frequency converters.

Fully automatic water supply and pressure boosting system, operated either from the mains or from a tank for private, commercial, industrial and municipal applications (back-up pump according to DIN 1988 and DIN EN 806 must be provided).

Approved pumped liquid is generally water that does not have aggressive chemical and mechanical effects on the materials used and does not contain abrasive and long-fibre constituents, such as

| Product designation | Network connection | Number of pumps | Number of standby pumps | Maximum working pressure PN | Gross weight approx. m | Article number |

|---|---|---|---|---|---|---|

| SiBoost Smart 1 Helix VE 204 | 3~380 V, 50/60 Hz | 1 | 0 | 16 bar | 75.0 kg | 2450169 |

| SiBoost Smart 1 Helix VE 206 | 3~380 V, 50/60 Hz | 1 | 0 | 16 bar | 77.0 kg | 2450170 |

| SiBoost Smart 1 Helix VE 208 | 3~400 V, 50 Hz | 1 | 0 | 16 bar | 78.0 kg | 2450171 |

| SiBoost Smart 1 Helix VE 211 | 3~380 V, 50/60 Hz | 1 | 0 | 16 bar | 89.0 kg | 2450172 |

| SiBoost Smart 1 Helix VE 403 | 3~400 V, 50 Hz | 1 | 0 | 16 bar | 74.0 kg | 2450173 |

| SiBoost Smart 1 Helix VE 404 | 3~400 V, 50 Hz | 1 | 0 | 16 bar | 77.0 kg | 2450174 |

| SiBoost Smart 1 Helix VE 405 | 3~400 V, 50 Hz | 1 | 0 | 16 bar | 77.0 kg | 2450175 |

| SiBoost Smart 1 Helix VE 407 | 3~400 V, 50 Hz | 1 | 0 | 16 bar | 87.0 kg | 2450176 |

| SiBoost Smart 1 Helix VE 410 | 3~400 V, 50 Hz | 1 | 0 | 16 bar | 89.0 kg | 2450177 |

| SiBoost Smart 1 Helix VE 603 | 3~400 V, 50 Hz | 1 | 0 | 16 bar | 77.0 kg | 2450178 |

| SiBoost Smart 1 Helix VE 603 | 3~400 V, 50 Hz | 1 | 0 | 16 bar | 78.0 kg | 2450179 |

| SiBoost Smart 1 Helix VE 604 | 3~400 V, 50 Hz | 1 | 0 | 16 bar | 88.0 kg | 2450180 |

| SiBoost Smart 1 Helix VE 606 | 3~400 V, 50 Hz | 1 | 0 | 16 bar | 90.0 kg | 2450181 |

| SiBoost Smart 1 Helix VE 603 | 3~400 V, 50 Hz | 1 | 0 | 16 bar | 113.0 kg | 2450182 |

| SiBoost Smart 1 Helix VE 611 | 3~400 V, 50 Hz | 1 | 0 | 16 bar | 116.0 kg | 2450183 |

| SiBoost Smart 1 Helix VE 1002 | 3~380 V, 50/60 Hz | 1 | 0 | 16 bar | 90.0 kg | 2450184 |

| SiBoost Smart 1 Helix VE 1003 | 3~380 V, 50/60 Hz | 1 | 0 | 16 bar | 92.0 kg | 2450185 |

| SiBoost Smart 1 Helix VE 1005 | 3~380 V, 50/60 Hz | 1 | 0 | 16 bar | 115.0 kg | 2450186 |

| SiBoost Smart 1 Helix VE 1006 | 3~380 V, 50/60 Hz | 1 | 0 | 16 bar | 116.0 kg | 2450187 |

| SiBoost Smart 1 Helix VE 1602 | 3~380 V, 50/60 Hz | 1 | 0 | 16 bar | 100.0 kg | 2450189 |

| SiBoost Smart 1 Helix VE 1603/3kW | 3~380 V, 50/60 Hz | 1 | 0 | 16 bar | 124.0 kg | 2450190 |

| SiBoost Smart 1 Helix VE 1603/4kW | 3~380 V, 50/60 Hz | 1 | 0 | 16 bar | 106.0 kg | 2450191 |

| SiBoost Smart 1 Helix VE 1605 | 3~380 V, 50/60 Hz | 1 | 0 | 16 bar | 150.0 kg | 2450192 |

| SiBoost Smart 1 Helix VE 1606 | 3~380 V, 50/60 Hz | 1 | 0 | 16 bar | 155.0 kg | 2450193 |

| SiBoost Smart 1 Helix VE 2202-3 | 3~380 V, 50/60 Hz | 1 | 0 | 16 bar | 154.0 kg | 2450194 |

| SiBoost Smart 1 Helix VE 2202-4 | 3~380 V, 50/60 Hz | 1 | 0 | 16 bar | 154.0 kg | 2450195 |

| SiBoost Smart 1 Helix VE 2203 | 3~380 V, 50/60 Hz | 1 | 0 | 16 bar | 173.0 kg | 2450196 |

| SiBoost Smart 1 Helix VE 2204 | 3~380 V, 50/60 Hz | 1 | 0 | 16 bar | 179.0 kg | 2450197 |

| SiBoost Smart 1 Helix VE 2205 | 3~380 V, 50/60 Hz | 1 | 0 | 16 bar | 312.0 kg | 2450198 |

| SiBoost Smart 1 Helix VE 3602-7,5 | 3~380 V, 50/60 Hz | 1 | 0 | 16 bar | 188.0 kg | 2450199 |

| SiBoost Smart 1 Helix VE 3604 | 3~380 V, 50/60 Hz | 1 | 0 | 16 bar | 346.0 kg | 2450200 |

| SiBoost Smart 1 Helix VE 3605 | 3~380 V, 50/60 Hz | 1 | 0 | 16 bar | 351.0 kg | 2450201 |

| SiBoost Smart 1 Helix VE 5202 | 3~380 V, 50/60 Hz | 1 | 0 | 16 bar | 210.0 kg | 2450202 |

| SiBoost Smart 1 Helix VE 5203 | 3~380 V, 50/60 Hz | 1 | 0 | 16 bar | 360.0 kg | 2450203 |

| SiBoost Smart 1 Helix VE 5204 | 3~380 V, 50/60 Hz | 1 | 0 | 16 bar | 375.0 kg | 2450204 |

| SiBoost Smart 1 Helix VE 5205 | 3~380 V, 50/60 Hz | 1 | 0 | 16 bar | 392.0 kg | 2450205 |

Baseframe: galvanized steel, with height adjustable anti-vibration mounts, providing good casing sound insulation, and integral rigging points.

Piping system: Complete piping system in stainless steel on the pressure side, suitable for connecting pipes of all common materials. The piping system is designed according to the total hydraulic capacity of the pressure boosting unit

Pumps: 1 Helix VE 2 to Helix VE 52 series pump is used.

Air-cooled frequency converters on the pump motor ensure infinitely variable speed control between 25 Hz and a maximum of 60 Hz for all pumps of this series. 60 Hz.

Valves: The pump is equipped on the pressure side with a ball check valve as standard with DVGW approval mark and (on the pressure side) with a non-return valve with DVGW/KTW approval.

Diaphragm pressure vessel 8 l/PN 16 on the discharge side with a butyl rubber diaphragm, DVGW/KTW approval, compliant with food safety laws, equipped with a shut-off ball cock for inspection and testing purposes, with a drainage system and flow fittings with DVGW/KTW approval to DIN 4807.

Pressure monitoring: 2 pressure sensors: 4...20 mA, located on the pressure side and on the suction side.

Pressure display: Pressure gauge located on the suction and final pressure sides.

Other versions on request

The Wilo CAD online library contains DWG drawings of Wilo pumping equipment. In this library, the dimensions of the pumping equipment are given as a guideline. Please note that the contents of the Wilo CAD online library are subject to technical changes.

We will tell you in detail about our services, types of work and typical projects, calculate the cost and prepare an individual offer!