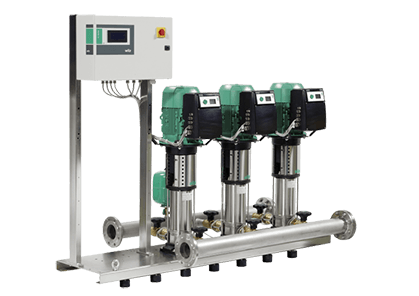

| Example: | Wilo-COR-1 MHIE 205 / GE |

| CO | Compact pressure boosting system |

| R | Regulation with a frequency converter |

| 1 | Single pump |

| MHIE | Pump Series |

| 2 | Nominal volume flow of single pump [m 3 / h] |

| 05 | Number of single pump sections |

| GE | Main unit, i.e. without additional control device |

Water supply systems with normal-suction high-pressure centrifugal pump and integrated speed control

The Wilo CAD online library contains DWG drawings of Wilo pumping equipment. In this library, the dimensions of the pumping equipment are given as a guideline. Please note that the contents of the Wilo CAD online library are subject to technical changes.

We will tell you in detail about our services, types of work and typical projects, calculate the cost and prepare an individual offer!