| Example: | Wilo-Rexa CUT GE03.26/P-T15-2-540X/P |

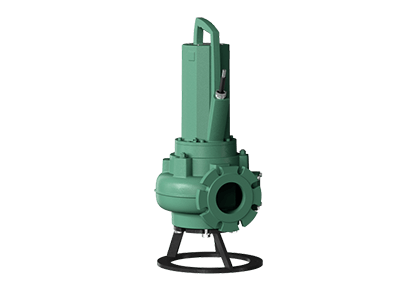

| Rexa | Submersible wastewater pump |

| CUT | CUT series |

| GE | Hydraulic version: GI — internal cutting mechanism GE — external cutting mechanism |

| 03 | Nominal diameter of the pressure connection: 03 = DN 32 04 = DN 40 |

| 26 | Pressure at zero flow in m |

| P | Type of motor: S — stainless steel motor housing P — motor housing in grey cast iron |

| T | Mains connection version: M = 1~ T = 3~ |

| 15 | Value/10 — motor power P2 in kW |

| 2 | Number of poles |

| 5 | Frequency (5=50Hz, 6=60Hz) |

| 40 | Mains voltage |

| X | Explosion-proof version: Without additional code — without explosion-proof design X — with explosion-proof version |

| P | Peripheral electrical equipment: without additional code — with cable with free end P = with plug |

Submersible sewage pump with macerator for intermittent and continuous operation for stationary and portable wet well installation

| Product designation | Article number |

|---|---|

| Rexa CUT GE03.20/P-T15-2-540X | 6075981 |

| Rexa CUT GE03.34/P-T39-2-540X 20m | 6079713 |

| Rexa CUT GE03.25/P-T25-2-540X 20m | 6079714 |

| Rexa CUT GE03.20/P-T15-2-540X 20m | 6080435 |

| list | 6080483 |

| Rexa CUT GI03.26/S-T15-2-540 | 2458800 |

| list | 2458801 |

| Rexa CUT GE03.25/P-T25-2-540X | 2780026 |

| Rexa CUT GE03.34/P-T39-2-540X | 2780027 |

| Rexa CUT GI03.29/S-M15-2-523/P | 2780030 |

| Rexa CUT GI03.29/S-T15-2-540 | 2780031 |

| Rexa CUT GI03.26/S-M15-2-523/P | 2458804 |

Submersible sewage pump with internal or external macerator as submersible monobloc unit for stationary and portable wet well installation and for intermittent and continuous operation.

Hydraulic section

Horizontal pressure connection for flange connection with DN 32/40 combi-flange connection. The maximum possible dry matter content is 8 % (depending on the type of hydraulic part). Single channel and multi-vane impellers are available.

Electric motor

Surface-cooled motors in single-phase and three-phase versions for direct starting are used. The heat is given off directly to the environment via the motor housing. Electric motors can operate in immersed state in continuous duty (S1), and in non-immersed state - in intermittent duty (S2) or intermittent duty (S3).

The motors are equipped with winding temperature sensors. They protect the motor windings from overheating. According to the standard, bimetal sensors are used for this purpose. motors of version P are additionally equipped with an internal leakage monitor of the motor chamber. The leakage control electrode signals the ingress of water into the motor chamber.

In addition, the motors can be equipped with an external rod electrode for leakage control of the seal chamber. The electrode signals the ingress of water into the seal chamber through the seal on the pumped liquid side.

The power cable is of standard length 10 m and is equipped with a plug for single-phase electric motor. The three-phase electric motor according to the standard has a loose cable end, and is longitudinally sealed on electric motors of version P.

Sealing

There is a seal chamber between the electric motor and the hydraulic part. It is filled with white medical grade Vaseline oil and protects the electric motor from fluid ingress through the seal on the pump side. Sealing at pump and motor side is accomplished by two end seals which rotate independently of each other.

The Wilo CAD online library contains DWG drawings of Wilo pumping equipment. In this library, the dimensions of the pumping equipment are given as a guideline. Please note that the contents of the Wilo CAD online library are subject to technical changes.

We will tell you in detail about our services, types of work and typical projects, calculate the cost and prepare an individual offer!