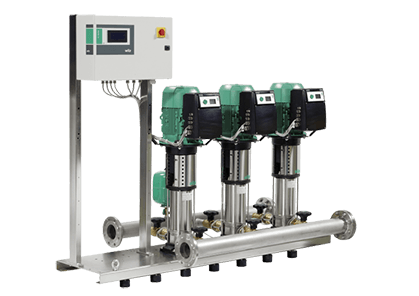

| Example: | Wilo-SiBoost Smart 3 MVISE 406 |

| SiBoost Smart | Compact pressure booster system with integrated speed control |

| 3 | Number of pumps |

| MVISE | Pump series |

| 4 | Nominal flow [m3/h] of single pump |

| 06 | Number of stages of single pump |

Optimal pump load regulation thanks to variable pressure control (pv) and parallel synchronous speed control for additional energy savings

Noise levels up to 20 dB(A) lower than in conventional systems at comparable hydraulic output

Very wide frequency converter control range: 20 Hz to a maximum of 50 Hz

Maintenance-free pump type without mechanical seals

High reliability due to various safety functions including overload protection, dry run protection and automatic shutdown

SCe control unit makes the system easy to set up and operate, thanks to LCD display and green adjusting button

Potable water tolerance for all components in contact with pumped media

Ready for integration into building automation system with SCe control unit via Modbus RTU serial protocol

Low-noise, ready for connection water-supply unit with 2 to 4 vertically arranged vertically arranged normal-suction stainless steel high-pressure multistage centrifugal pumps of the MVISE range in glanded version. Each pump is equipped with a built-in water-cooled frequency converter. The system is equipped with the Smart Controller SCe.

MVISE 2 – 8 m3/h

Foundation frame: Zinc-plated steel, with height-adjustable anti-vibration mounts for good structure-borne sound insulation, as well as integrated support points and conduit.

Piping system: all stainless steel piping used to connect piping of any material used in structural engineering; the piping system must be sized to match the total hydraulic capacity of the pressure booster unit

Pumps: 2 to 4 MVISE 2, 4, 8 pumps connected in parallel are used. Fittings: every pump is equipped on the suction and pressure sides with a ball shut-off valve with DVGW approval mark or ring-valve shut-off valves and, on the pressure side, with a non-return valve with DVGW approval.

The 8 l/PN 16 diaphragm pressure vessel is located on the discharge side with a butyl rubber diaphragm, is DVGW/KTW approved, fulfils the requirements of the Food Safety Act; it has a shut-off ball cock, a drainage system and flow fittings with DVGW/KTW approval in accordance with DIN 4807 for testing and inspection purposes.

Pressure monitoring: 2 pressure sensors: 4…20 mA, located on the pressure side and suction side.

Pressure monitoring: 2 pressure sensors: 4…20 mA, located on the pressure side and suction side.

Pressure indication: Pressure gauge is located on suction and end pressure sides.

Pressure control panel: 4…20 mA pressure gauges are located on the pressure side.

Control Panel: Smart Controller SCe with LCD display as standard.

Other versions on request

The Wilo CAD online library contains DWG drawings of Wilo pumping equipment. In this library, the dimensions of the pumping equipment are given as a guideline. Please note that the contents of the Wilo CAD online library are subject to technical changes.

We will tell you in detail about our services, types of work and typical projects, calculate the cost and prepare an individual offer!