| Example | Stratos MAXO-D 40/0.5-8 |

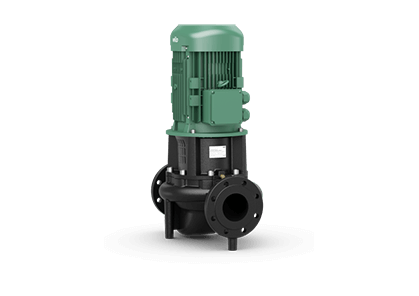

| Stratos MAXO | High efficiency pump (flanged pump), electronically controlled |

| D | Twin pump |

| 40/ | Nominal connection diameter |

| 0.5-8 | Rated head [m] |

Intuitive operation thanks to the Setup Guide application function in combination with the new display and the control button with green button technology.

Highest energy efficiency through a combination of optimized and innovative energy-saving functions (e.g. No-Flow Stop).

Optimal system efficiency thanks to new, innovative and intelligent control functions such as Dynamic Adapt plus, Multi-Flow Adaptation, T-const. and ΔT-const.

Latest communication interfaces (e.g. Bluetooth) for the connection to mobile devices and direct networking of the pumps via the Wilo Net for the control of several pumps.

Maximum convenience in terms of electrical installation thanks to the clear and ergonomic terminal box and the optimized Wilo-Connector.

A leap into the world of the future

More efficiency, networkability and convenience than ever before - the Wilo-Stratos MAXO and Wilo-Stratos MAXO-D lead you into the future of pumping technology. The world's first intelligent pump* makes life today easier and incorporates the innovations of tomorrow.

Type

Smart dual wet-rotor circulation pump with threaded connection or flange connection, EC motor with integrated electronic power control.

Application

All hot water heating systems, air-conditioning systems, closed cooling circuits, industrial circulation systems.

Equipment/function

Applications

The pump enables fine-tuning of the control method for the specific application in each individual installation (e.g. radiator, underfloor heating, ceiling cooling) while operating at the highest efficiency.

Heating

Cooling

Combination of heating and cooling

Depending on the selected application, the following control methods are available:

Modes of control

Optional functions

Manual settings

Automatic control

External control inputs and functions

2 analog inputs:

2 digital inputs:

Wilo Net for control of twin pumps (two single pumps), coupling of several pumps and remote pump control via gateway

Alarms and display

Display status indication of the operating mode:

| Product designation | .Mains connection | Energy Efficiency Index (EEI) | Maximum working pressure &#nbsp;PN | .Pipeline connection | .Mounting length l0 | Gross weight approx. m | Runaway Q max add | Pressure H max | Article number | .

|---|---|---|---|---|---|---|---|---|---|

| Stratos MAXO-D 30/0,5-6 PN 10 | 1~230 V, 50/60 Hz | 0.19 | 10 бар | G 2 | 180 мм | 20.6 кг | 13.5 м³/ч | - | 2164645 |

| Stratos MAXO-D 30/0,5-10 PN 10 | 1~230 V, 50/60 Hz | 0.19 | 10 бар | G 2 | 180 мм | 21.2 кг | 17.8 м³/ч | - | 2164646 |

| Stratos MAXO-D 30/0,5-6 PN 16 | 1~230 V, 50/60 Hz | 0.19 | 16 бар | G 2 | 180 мм | 20.6 кг | 13.5 м³/ч | - | 2186289 |

| Stratos MAXO-D 30/0,5-10 PN 16 | 1~230 V, 50/60 Hz | 0.19 | 16 бар | G 2 | 180 мм | 21.2 кг | 17.8 м³/ч | - | 2186290 |

| Stratos MAXO-D 32/0,5-8 PN 6/10 | 1~230 V, 50/60 Hz | 0.19 | 10 бар | DN 32 | 220 мм | 24.9 кг | 18.0 м³/ч | - | 2164647 |

| Stratos MAXO-D 32/0,5-12 PN 6/10 | 1~230 V, 50/60 Hz | 0.19 | 10 бар | DN 32 | 220 мм | 25.5 кг | 23.0 м³/ч | - | 2164648 |

| Stratos MAXO-D 40/0,5-8 PN 6/10 | 1~230 V, 50/60 Hz | 0.18 | 10 бар | DN 40 | 220 мм | 27.6 кг | 29.0 м³/ч | - | 2164649 |

| Stratos MAXO-D 40/0,5-12 PN 6/10 | 1~230 V, 50/60 Hz | 0.17 | 10 бар | DN 40 | 250 мм | 38.8 кг | 39.0 м³/ч | - | 2164650 |

| Stratos MAXO-D 40/0,5-16 PN 6/10 | 1~230 V, 50/60 Hz | 0.17 | 10 бар | DN 40 | 250 мм | 38.8 кг | 42.0 м³/ч | - | 2164651 |

| Stratos MAXO-D 50/0,5-6 PN 6/10 | 1~230 V, 50/60 Hz | 0.18 | 10 бар | DN 50 | 240 мм | 30.5 кг | 33.0 м³/ч | - | 2164652 |

| Stratos MAXO-D 50/0,5-8 PN 6/10 | 1~230 V, 50/60 Hz | 0.17 | 10 бар | DN 50 | 240 мм | 41.1 кг | 42.0 м³/ч | - | 2164653 |

| Stratos MAXO-D 50/0,5-9 PN 6/10 | 1~230 V, 50/60 Hz | 0.17 | 10 бар | DN 50 | 280 мм | 41.1 кг | 52.0 м³/ч | - | 2164654 |

| Stratos MAXO-D 50/0,5-12 PN 6/10 | 1~230 V, 50/60 Hz | 0.17 | 10 бар | DN 50 | 280 мм | 41.1 кг | 53.0 м³/ч | - | 2164655 |

| Stratos MAXO-D 50/0,5-16 PN 6/10 | 1~230 V, 50/60 Hz | 0.17 | 10 бар | DN 50 | 340 мм | 66.8 кг | 75.0 м³/ч | - | 2164656 |

| Stratos MAXO-D 65/0,5-6 PN 6/10 | 1~230 V, 50/60 Hz | 0.17 | 10 бар | DN 65 | 280 мм | 44.9 кг | 52.0 м³/ч | - | 2164657 |

| Stratos MAXO-D 65/0,5-12 PN 6/10 | 1~230 V, 50/60 Hz | 0.17 | 10 бар | DN 65 | 340 мм | 66.6 кг | 71.0 м³/ч | - | 2164658 |

| Stratos MAXO-D 65/0,5-16 PN 6/10 | 1~230 V, 50/60 Hz | 0.17 | 10 бар | DN 65 | 340 мм | 66.8 кг | 78.0 м³/ч | - | 2164659 |

| Stratos MAXO-D 80/0,5-6 PN 6 | 1~230 V, 50/60 Hz | 0.18 | 6 бар | DN 80 | 360 мм | 68.3 кг | 87.0 м³/ч | - | 2164660 |

| Stratos MAXO-D 80/0,5-6 PN 10 | 1~230 V, 50/60 Hz | 0.18 | 10 бар | DN 80 | 360 мм | 68.3 кг | 87.0 м³/ч | - | 2164661 |

| Stratos MAXO-D 80/0,5-12 PN 6 | 1~230 V, 50/60 Hz | 0.17 | 6 бар | DN 80 | 360 мм | 70.5 кг | 104.0 м³/ч | - | 2164662 |

| Stratos MAXO-D 80/0,5-12 PN 10 | 1~230 V, 50/60 Hz | 0.17 | 10 бар | DN 80 | 360 мм | 70.5 кг | 104.0 м³/ч | - | 2164663 |

| Stratos MAXO-D 80/0,5-16 PN 6 | 1~230 V, 50/60 Hz | 0.17 | 6 бар | DN 80 | 360 мм | 70.5 кг | 112.0 м³/ч | - | 2164664 |

| Stratos MAXO-D 80/0,5-16 PN 10 | 1~230 V, 50/60 Hz | 0.17 | 10 бар | DN 80 | 360 мм | 70.5 кг | 112.0 м³/ч | - | 2164665 |

| Stratos MAXO-D 32/0,5-8 PN 16 | 1~230 V, 50/60 Hz | 0.19 | 16 бар | DN 32 | 220 мм | 24.9 кг | 18.0 м³/ч | - | 2186291 |

The Wilo CAD online library contains DWG drawings of Wilo pumping equipment. In this library, the dimensions of the pumping equipment are given as a guideline. Please note that the contents of the Wilo CAD online library are subject to technical changes.

We will tell you in detail about our services, types of work and typical projects, calculate the cost and prepare an individual offer!