Layout Solutions

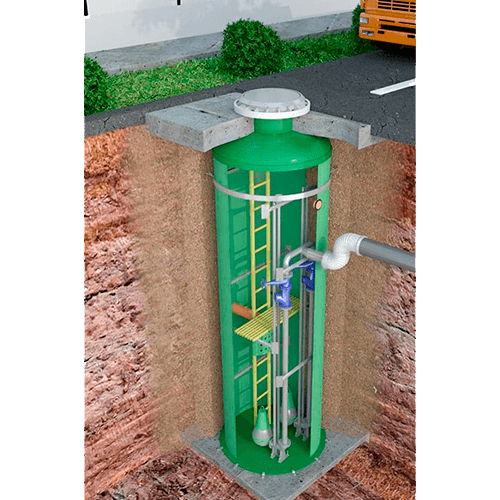

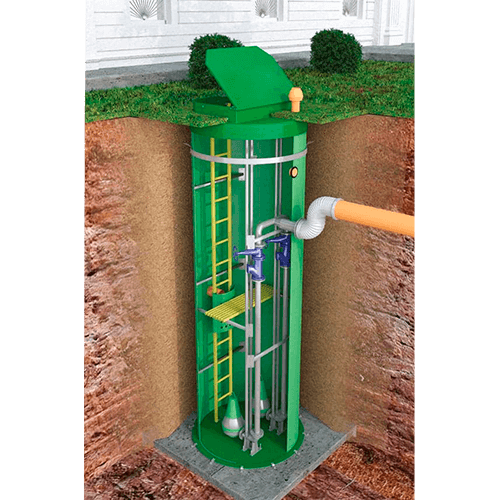

The structural basis of the station is formed by the following components:

- Inlet storage compartment

- Pumping equipment section

- Pipeline communications network

- Set of shut-off mechanisms

- Automated control system

- Supply and exhaust ventilation

Work cycle

The functional algorithm is implemented through a sequence of actions:

- Reception of incoming wastewater in the storage chamber

- Fill level monitoring with sensors

- Activation of pumping equipment when the threshold value is reached

- Transportation Discharge through a pressure manifold

- Pump shutdown when the level drops below a set limit

Advantageous characteristics

Advantageous featuresof standard pumping stations:

- Ready-made design solutions

- Accelerated documentation development time

- Cost-effectiveness

- Interchangeability of components

- Ease of installation and maintenance

Practical application

Target areasof use:

- Residential development

- Industrial areas

- Social facilities

- Utilities

- Drainage Systems

Technical Equipment

Main Equipment Arsenal:

- Centrifugal Pumping Units

- Automatic Control Systems

- Sensor Level Control Systems

- Protection Mechanisms

- Signaling Devices

Operating Regulations

Preventive Measures Include:

- Pump Park Performance Testing

- Tank Sanitation

- Automation Functionality Check

- Joint Tightness Monitoring

- Preventive Repairs

Technological Development

Current Design Trends:

- Use of Energy-Saving Technologies

- Installation of Remote Monitoring Systems

- Use of Materials with Increased Corrosion Resistance

- Improvement of Automated Systems

- Implementation of Modular Designs

Standard sewage pumping stations remain a popular solution in the wastewater sector due to their adaptability, reliability, and reasonable cost. Technological innovations are continuously improving their performance and ease of use.