Overview

Basic Parameters

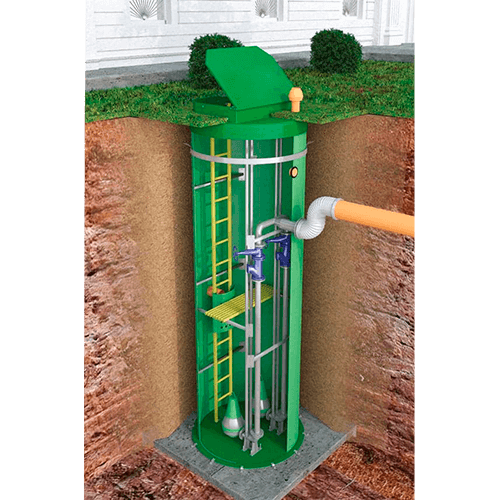

This type of engineering structure is a modern process unit that provides forced transport of sewage using submersible pumping units. A distinctive design feature is the presence of a special above-ground unit, which significantly simplifies equipment maintenance.

Application Areas

- Remote Areas — Facilities located at a significant distance from populated areas

- Control Points — Locations requiring continuous monitoring of system operation

- Installation Sites — Areas requiring the installation of lifting equipment for pump maintenance

- Cold Regions — Areas with the potential for deep soil freezing

Design Features

The unit's body is manufactured from high-quality fiberglass using machine-winding technology. The kit includes the following components:

- Launch mechanism — a ladder for the safe movement of personnel (a corrosion-resistant version is available)

- Work area — a special platform that is installed for housing lengths exceeding 3 meters

- Filtering element — a basket for trapping large impurities at the inlet of the supply pipeline

- Installation system — an automated mechanism for the quick installation of pumping equipment

Service unit functionality

The ground module performs a number of critical functions:

- Monitoring — the ability to continuously monitor the operation of all systems

- Technical equipment — creating optimal conditions for installing the lifting mechanism

- Protection — reliable insulation of equipment from adverse weather conditions

- Thermal control — preventing soil freezing through effective thermal insulation

Technological equipment

- Pumping complex — submersible units with an automatic control system

- Pipeline network — stainless steel main lines

- Instrumentation — shut-off valve Valves with check valves

- Ventilation — air exchange system

- Automation — control cabinet with liquid level sensors

Advantageous Features

- Maintenance — simplified installation and removal of pumping equipment

- Climate Protection — effective thermal insulation against low temperatures

- Monitoring — convenient access for visual monitoring of system operation

- Mechanization — ability to integrate lifting devices

- Wear Resistance — use of durable materials in the design

Extended Functionality

- Thermal Protection — reinforced housing insulation

- Digital Automation — modern control system

- Remote Control — GSM module for remote monitoring

- Safety — explosion-proof design of components

- Filtration — additional wastewater treatment modules

This sewage pumping station configuration is ideal for facilities where continuous monitoring of equipment operation and ease of maintenance are critical.