| for example, | Wilo-Sub TWU 3-0305-HS-E-CP |

| TWU | Submersible pump |

| 3 | Diameter of hydraulic equipment in inches ["] |

| 03 | Nominal volumetric flow rate [m3/h] |

| 05 | Number of hydraulic sections |

| HS | High Speed |

| E | Frequency converter versionE = External frequency converterI = Internal frequency converter |

| CP | Control functionCP = Constant pressure maintenance without = Fixed speed up to 8400 rpm |

Constant, adjustable pressure thanks to external frequency converter with integrated control (TWU 3 HS-ECP)

Simple installation without additional pressure control sensors (TWU 3 HS-ECP)

High throughput thanks to built-in frequency converter with constant motor speed of 8400 rpm (TWU 3 HS-I)

Lower drilling and installation costs due to smaller diameter and less construction work

Extensive protection and monitoring features for safe operation

3" variable speed multistage submersible pump in shrouded version for vertical or horizontal installation

| Definition | .Mains | Motor diameter DM | Pressure head max. Hmax | Power output max. Qmax | Motor power P2 | Gross weight approx. m | Article |

|---|---|---|---|---|---|---|---|

| Sub TWU 3.02-02-HS-I | 1~230 V, 50/60 Hz | 76 mm | 37.1 m | 3.6 m³/h | 0.60 kW | 9.8 kW | 6064276 |

| Sub TWU 3.02-04-HS-I | 1~230 V, 50/60 Hz | 76 mm | 74.7 m | 3.6 m³/h | 0.90 kW | 11.0 kW | 6064277 |

| Sub TWU 3.02-05-HS-I | 1~230 V, 50/60 Hz | 76 mm | 93.2 m | 3.6 m³/h | 0.90 kW | 11.2 kW | 6064278 |

| Sub TWU 3.02-06-HS-I | 1~230 V, 50/60 Hz | 76 mm | 112.4 m | 3.6 m³/h | 1.50 kW | 12.8 kW | 6064279 |

| Sub TWU 3.03-02-HS-I | 1~230 V, 50/60 Hz | 76 mm | 42.9 m | 5.0 m³/h | 0.60 kW | 9.8 kW | 6064280 |

| Sub TWU 3.03-03-HS-I | 1~230 V, 50/60 Hz | 76 mm | 64.3 m | 5.0 m³/h | 0.90 kW | 10.7 kW | 6064281 |

| Sub TWU 3.03-04-HS-I | 1~230 V, 50/60 Hz | 76 mm | 84.7 m | 5.0 m³/h | 1.50 kW | 12.4 kW | 6064282 |

| Sub TWU 3.05-01-HS-I | 1~230 V, 50/60 Hz | 76 mm | 25.2 m | 6.5 m³/h | 0.60 kW | 9.5 kW | 6064283 |

| Sub TWU 3.05-03-HS-I | 1~230 V, 50/60 Hz | 76 mm | 69.4 m | 6.5 m³/h | 0.90 kW | 10.7 kW | 6064284 |

| Sub TWU 3.05-04-HS-I | 1~230 V, 50/60 Hz | 76 mm | 90.4 m | 6.5 m³/h | 1.50 kW | 12.4 kW | 6064285 |

| Sub TWU 3.02-04-HS-ECP-B | 1~230 V, 50/60 Hz | 76 mm | 73.9 m | 5.1 m³/h | 0.60 kW | 7.0 kW | 6079396 |

| Sub TWU 3.02-06-HS-ECP-B | 1~230 V, 50/60 Hz | 76 mm | 107.0 m | 5.0 m³/h | 0.90 kW | 7.6 kW | 6079397 |

| Sub TWU 3.02-09-HS-ECP-B | 1~230 V, 50/60 Hz | 76 mm | 161.4 m | 4.9 m³/h | 1.50 kW | 8.0 kW | 6079398 |

| Sub TWU 3.03-03-HS-ECP-B | 1~230 V, 50/60 Hz | 76 mm | 58.2 m | 6.4 m³/h | 0.60 kW | 6.9 kW | 6079399 |

| Sub TWU 3.03-05-HS-ECP-B | 1~230 V, 50/60 Hz | 76 mm | 95.2 m | 6.4 m³/h | 0.90 kW | 7.5 kW | 6079400 |

| Sub TWU 3.03-08-HS-ECP-B | 1~230 V, 50/60 Hz | 76 mm | 151.5 m | 6.6 m³/h | 1.50 kW | 7.9 kW | 6079401 |

| Sub TWU 3.05-04-HS-ECP-B | 1~230 V, 50/60 Hz | 76 mm | 58.7 m | 8.9 m³/h | 0.90 kW | 7.5 kW | 6079402 |

| Sub TWU 3.05-07-HS-ECP-B | 1~230 V, 50/60 Hz | 76 mm | 102.2 m | 8.8 m³/h | 1.50 kW | 7.9 kW | 6079403 |

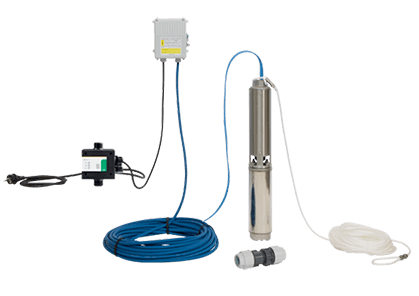

Submersible pump:

Frequency converter for "HS-E..." version:

Description/construction

Submersible drainage pump for vertical or horizontal installation.

Hydraulics

Multistage submersible multi-stage radial impeller pump in split casing design. With integrated non-return valve. All parts in contact with pumped media are made of corrosion resistant material.

Electric motor

Non-corrosive asynchronous electric motor for connection to the frequency converter included in the delivery (HS-E...) or for direct connection to the electric network (HS-I...). Rewindable oil-filled electric motor with self-lubricating bearings, designed for high speeds up to 8400 rpm.

Frequency Converter (FC)

Control function "CP": Constant pressure

Through operation with a frequency converter the speed of the unit is automatically adapted to the current water flow rate. In this way, the submersible pump always delivers a constant pressure.

Cooling

The motor is cooled by the fluid being pumped. The motor may only be operated in immersed state. The maximum temperature limits for the pumped liquid and its minimum flow speed must be observed.

For vertical installation a cooling jacket must be provided depending on the diameter of the well. Horizontal installation is always done with a cooling jacket.

The external frequency converter is also cooled by the fluids being pumped. For this purpose, the frequency converter must be installed directly in the pipeline outside the pumped fluids (with flood protection).

The Wilo CAD online library contains DWG drawings of Wilo pumping equipment. In this library, the dimensions of the pumping equipment are given as a guideline. Please note that the contents of the Wilo CAD online library are subject to technical changes.

We will tell you in detail about our services, types of work and typical projects, calculate the cost and prepare an individual offer!