Compresso are pressure maintenance units with compressors for heating, cooling and solar systems. They are especially suitable in situations where compactness and precision are required, and are used in medium power systems.

Pressure maintenance systems with compressors

Compresso are pressure maintenance units with compressors for heating, cooling and solar systems. They are especially suitable in situations where compactness and precision are required, and are used in medium power systems.

Key features

BrainCube control unit

Self-diagnosis with memory function.

Fillsafe make-up control

With the possibility of adjusting the water make-up Pleno P.

TECHNICAL SPECIFICATIONS - TECBOX

Application area:

Heating systems, refrigeration systems, solar systems.

For systems in accordance with EN 12828, SWKI 93-1, solar systems in accordance with EN 12976, ENV 12977 local temperature protection in case of power failure.

Pressure:

Minimum allowable pressure, PSmin: 0 bar

Maximum allowable pressure, PS: see article numbers

Temperature:

Maximum permissible ambient temperature, TA: 40 ° C

Minimum permissible ambient temperature, TAmin: 5 ° C

Error:

Precise pressure maintenance ± 0.1 bar.

Supply voltage:

230 V / 50 Hz

Precise pressure maintenance ± 0.1 bar. Designed to work with an external oil-free compressor. 1 inlet and 1 vent valve

| A type | PS[bar] | B | H | T | m[kg] | Pel[kW] | EAN | № product |

|---|---|---|---|---|---|---|---|---|

| CX-6 | 6 | 450 | 250 | 260 | 15 | 0,1 | 7640148630740 | 810 1204 |

| CX-10 | 10 | 450 | 250 | 260 | 15 | 0,1 | 7640148630757 | 810 1206 |

| CX-16 | 16 | 450 | 250 | 260 | 15 | 0,1 | 7640148630764 | 810 1208 |

T = device depth

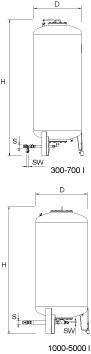

Primary tank. Measuring foot for level measurement. The kit includes a flexible connector for connection on the water side, a shut-off valve for quick emptying of the tank.

| A type | VN[l] | D | H* | HT*** | m[kg] | S | Sw | EAN | № products |

|---|---|---|---|---|---|---|---|---|---|

| 6 bar (PS) | |||||||||

| CU 200.6 | 200 | 500 | 1340 | 1565 | 34 | Rp1 | G3/4 | 7640148630771 | 712 1000 |

| CU 300.6 | 300 | 560 | 1469 | 1690 | 40 | Rp1 | G3/4 | 7640148630788 | 712 1001 |

| CU 400.6 | 400 | 620 | 1532 | 1760 | 58 | Rp1 | G3/4 | 7640148630795 | 712 1002 |

| CU 500.6 | 500 | 680 | 1627 | 1858 | 67 | Rp1 | G3/4 | 7640148630801 | 712 1003 |

| CU 600.6 | 600 | 740 | 1638 | 1873 | 80 | Rp1 | G3/4 | 7640148630818 | 712 1004 |

| CU 800.6 | 800 | 740 | 2132 | 2360 | 98 | Rp1 | G3/4 | 7640148630825 | 712 1005 |

VN = Nominal volume

Secondary tank. The kit includes a flexible connection for the water side connection, a shut-off valve for quick emptying of the tank, and a mounting kit for connecting the tanks on the air side.

| A type | VN[l] | D | H** | HT*** | m[kg] | S | Sw | EAN | № product |

|---|---|---|---|---|---|---|---|---|---|

| 6 bar (PS) | |||||||||

| CU 200.6 E | 200 | 500 | 1340 | 1565 | 33 | Rp1 | G3/4 | 7640148630832 | 712 2000 |

| CU 300.6 E | 300 | 560 | 1469 | 1690 | 39 | Rp1 | G3/4 | 7640148630849 | 712 2001 |

| CU 400.6 E | 400 | 620 | 1532 | 1760 | 57 | Rp1 | G3/4 | 7640148630856 | 712 2002 |

| CU 500.6 E | 500 | 680 | 1627 | 1858 | 66 | Rp1 | G3/4 | 7640148630863 | 712 2003 |

| CU 600.6 E | 600 | 740 | 1638 | 1873 | 79 | Rp1 | G3/4 | 7640148630870 | 712 2004 |

| CU 800.6 E | 800 | 740 | 2132 | 2360 | 97 | Rp1 | G3/4 | 7640148630887 | 712 2005 |

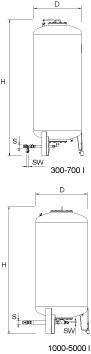

Primary tank. Measuring foot for level measurement. Internal anti-corrosion coating for minimal wear on the camera.

| A type* | VN[l] | D | H** | H*** | m[kg] | S | Sw | EAN | № products |

|---|---|---|---|---|---|---|---|---|---|

| 6 bar (PS) | |||||||||

| CG 300.6 | 300 | 500 | 1823 | 1839 | 140 | Rp1 | G3/4 | 7640148630894 | 712 1006 |

| CG 500.6 | 500 | 650 | 1864 | 1893 | 190 | Rp1 | G3/4 | 7640148630900 | 712 1007 |

| CG 700.6 | 700 | 750 | 1894 | 1931 | 210 | Rp1 | G3/4 | 7640148630917 | 712 1008 |

| CG 1000.6 | 1000 | 850 | 2097 | 2132 | 290 | Rp1 1/2 | G3/4 | 7640148630924 | 712 1009 |

| CG 1500.6 | 1500 | 1016 | 2248 | 2295 | 400 | Rp1 1/2 | G3/4 | 7640148630931 | 712 1010 |

| CG 2000.6 | 2000 | 1016 | 2746 | 2785 | 680 | Rp1 1/2 | G3/4 | 7640148630948 | 712 1015 |

| CG 3000.6 | 3000 | 1300 | 2850 | 2936 | 840 | Rp1 1/2 | G3/4 | 7640148630955 | 712 1012 |

| CG 4000.6 | 4000 | 1300 | 3496 | 3547 | 950 | Rp1 1/2 | G3/4 | 7640148630962 | 712 1013 |

| CG 5000.6 | 5000 | 1300 | 4134 | 4183 | 1050 | Rp1 1/2 | G3/4 | 7640148630979 | 712 1014 |

| 10 bar (PS) | |||||||||

| CG 300.10 | 300 | 500 | 1854 | 1866 | 160 | Rp1 | G3/4 | 7640148631075 | 712 3000 |

| CG 500.10 | 500 | 650 | 1897 | 1921 | 220 | Rp1 | G3/4 | 7640148631082 | 712 3001 |

| CG 700.10 | 700 | 750 | 1928 | 1961 | 250 | Rp1 | G3/4 | 7640148631099 | 712 3002 |

| CG 1000.10 | 1000 | 850 | 2097 | 2132 | 340 | Rp1 1/2 | G3/4 | 7640148631105 | 712 3003 |

| CG 1500.10 | 1500 | 1016 | 2285 | 2331 | 460 | Rp1 1/2 | G3/4 | 7640148631112 | 712 3004 |

| CG 2000.10 | 2000 | 1016 | 2779 | 2819 | 760 | Rp1 1/2 | G3/4 | 7640148631129 | 712 3009 |

| CG 3000.10 | 3000 | 1300 | 2879 | 2942 | 920 | Rp1 1/2 | G3/4 | 7640148631136 | 712 3006 |

| CG 4000.10 | 4000 | 1300 | 3524 | 3576 | 1060 | Rp1 1/2 | G3/4 | 7640148631143 | 712 3007 |

| CG 5000.10 | 5000 | 1300 | 4169 | 4211 | 1180 | Rp1 1/2 | G3/4 | 7640148631150 | 712 3008 |

VN = Nominal volume

| A type* | VN[l] | D | H** | H*** | m[kg] | S | Sw | EAN | № products |

|---|---|---|---|---|---|---|---|---|---|

| 6 bar (PS) | |||||||||

| CG 300.6 E | 300 | 500 | 1823 | 1839 | 140 | Rp1 | G3/4 | 7640148630986 | 712 2006 |

| CG 500.6 E | 500 | 650 | 1864 | 1893 | 190 | Rp1 | G3/4 | 7640148630993 | 712 2007 |

| CG 700.6 E | 700 | 750 | 1894 | 1931 | 210 | Rp1 | G3/4 | 7640148631006 | 712 2008 |

| CG 1000.6 E | 1000 | 850 | 2097 | 2132 | 290 | Rp1 1/2 | G3/4 | 7640148631013 | 712 2009 |

| CG 1500.6 E | 1500 | 1016 | 2248 | 2295 | 400 | Rp1 1/2 | G3/4 | 7640148631020 | 712 2010 |

| CG 2000.6 E | 2000 | 1016 | 2746 | 2785 | 680 | Rp1 1/2 | G3/4 | 7640148631037 | 712 2015 |

| CG 3000.6 E | 3000 | 1300 | 2850 | 2936 | 840 | Rp1 1/2 | G3/4 | 7640148631044 | 712 2012 |

| CG 4000.6 E | 4000 | 1300 | 3496 | 3547 | 950 | Rp1 1/2 | G3/4 | 7640148631051 | 712 2013 |

| CG 5000.6 E | 5000 | 1300 | 4134 | 4183 | 1050 | Rp1 1/2 | G3/4 | 7640148631068 | 712 2014 |

| 10 bar (PS) | |||||||||

| CG 300.10 E | 300 | 500 | 1854 | 1866 | 160 | Rp1 | G3/4 | 7640148631167 | 712 4000 |

| CG 500.10 E | 500 | 650 | 1897 | 1921 | 220 | Rp1 | G3/4 | 7640148631174 | 712 4001 |

| CG 700.10 E | 700 | 750 | 1928 | 1961 | 250 | Rp1 | G3/4 | 7640148631181 | 712 4002 |

| CG 1000.10 E | 1000 | 850 | 2097 | 2132 | 340 | Rp1 1/2 | G3/4 | 7640148631198 | 712 4003 |

| CG 1500.10 E | 1500 | 1016 | 2285 | 2331 | 460 | Rp1 1/2 | G3/4 | 7640148631204 | 712 4004 |

| CG 2000.10 E | 2000 | 1016 | 2779 | 2819 | 760 | Rp1 1/2 | G3/4 | 7640148631211 | 712 4009 |

| CG 3000.10 E | 3000 | 1300 | 2879 | 2942 | 920 | Rp1 1/2 | G3/4 | 7640148631228 | 712 4006 |

| CG 4000.10 E | 4000 | 1300 | 3524 | 3576 | 1060 | Rp1 1/2 | G3/4 | 7640148631235 | 712 4007 |

| CG 5000.10 E | 5000 | 1300 | 4169 | 4211 | 1180 | Rp1 1/2 | G3/4 | 7640148631242 | 712 4008 |

RS 485 interface for communication with the BrainCube control unit, 6 digital inputs for registering and displaying external potential-free signals, 9 digital potential-free outputs with the possibility of individual parameterisation, all outputs can have a feedback signal. Wall bracket, fixing elements for optimal cable routing.

| A type | B | H | T | m[kg] | Pel[kW] | EAN | № product |

|---|---|---|---|---|---|---|---|

| DCD | 270 | 230 | 260 | 0,5 | 0,1 | 7640148638715 | 814 1000 |

T = device depth

2 galvanically isolated 4-20 mA analog outputs for connection to a building management system, separate 2.5 kV AC power supply. Complete electrical installation in plastic housing, wall mounting.

| A type | B | H | T | m[kg] | Pel[kW] | EAN | № product |

|---|---|---|---|---|---|---|---|

| DCA | 190 | 260 | 180 | 0,5 | 0,1 | 7640148638739 | 814 1010 |

T = device depth

| A type | EAN | № product |

|---|---|---|

| DMS 2 C | 7640148638753 | 814 1020 |

Application area:

Only in conjunction with the TecBox control unit.

See annexes under the technical description - TecBox control unit.

Pressure:

Minimum allowable pressure, PSmin: 0 bar

Maximum allowable pressure, PS: see article numbers

Temperature:

Maximum permissible temperature, TS: 120 ° C

Minimum allowable temperature, TSmin: -10 ° C

Maximum allowable chamber temperature, TB: 70 ° C

Minimum permissible chamber temperature, TBmin: 5 ° C

Wednesday:

Non-corrosive and non-toxic media.

Antifreeze up to 50%.

Material:

Steel. Beryllium color.

Airproof butyl rubber chamber according to EN 13831 and Pneumatex internal standard.

Transport and storage:

In warm and dry places.

Standards:

Manufactured according to PED 2014/68 / EU.

Guarantee:

Compresso CG, CG… E: 5-year warranty for the airtight butyl rubber chamber.

Compresso CU, CU… E: 5-year tank warranty.

We will tell you in detail about our services, types of work and typical projects, calculate the cost and prepare an individual offer!