Compresso are pressure maintenance units with compressors for heating, cooling and solar systems. They are especially suitable for situations where compactness and precision are required, for medium power systems. The new BrainCube Connect control panel provides a new level of connectivity by providing connectivity to BMS, other BrainCubes control units, and remote control of the pressure maintenance system with sighting across the monitor screen.

For heating systems up to 12 MW, cooling up to 18 MW

Compresso are pressure maintenance units with compressors for heating, cooling and solar systems. They are especially suitable in situations where compactness and precision are required, and are used in medium power systems.

The new BrainCube Connect control panel provides a new level of connectivity by providing connectivity to the BMS, other BrainCubes control units, and the ability to remotely control the pressure maintenance system with a view on the monitor screen.

Key features

Improved design for easier and more convenient operation

Rugged 3.5-inch TFT, color, touchscreen display. User-friendly menu. Remote Internet access interface with remote control and sighting on the monitor screen. BrainCube Connect control panel integrated in TecBox.

Remote network access and troubleshooting

Remote network access and support for debug and commissioning operations, reducing the need for highly trained personnel before commissioning. Shorter response times, lower repair costs. Registration of data on checks of system performance indicators.

Modern connectivity

Typical means of connection to the BMS system and existing remote devices (RS485, Ethernet, USB), saving time for installation and maintenance, as well as controllability of the units. Communication with up to 8 BrainCubes in a master / slave network.

TECHNICAL SPECIFICATIONS - TECBOX

Application area:

Heating systems, refrigeration systems, solar systems.

For systems in accordance with EN 12828, SWKI 93-1, solar systems in accordance with EN 12976, ENV 12977 local temperature protection in case of power failure.

Pressure:

Minimum allowable pressure, PSmin: 0 bar

Maximum allowable pressure, PS: see article numbers

Temperature:

Maximum permissible ambient temperature, TA: 40 ° C

Minimum permissible ambient temperature, TAmin: 5 ° C

Error:

Precise pressure maintenance ± 0.1 bar.

Supply voltage:

Compresso C10: 1 x 230 V (-6% + 10%), 50/60 Hz

Compresso C15: 1 x 230 V (-6% + 10%), 50 Hz

Total electrical power consumption:

See part numbers.

Protection class:

IP 22 conforming to EN 60529

Noise level:

53-62 dB (A) / 1-10 bar

Material:

Steel, brass, aluminum

Transport and storage:

In warm and dry places.

Standards:

Manufactured according to

LV-D. 2014/35 / EU

EMC-D. 2014/30 / EU

Precise pressure maintenance ± 0.1 bar. 1 compressor. Manifold with one bypass valve and safety valve.

| A type | PS[bar] | B | H | T | m[kg] | Pel[kW] | EAN | № product |

|---|---|---|---|---|---|---|---|---|

| C 10.1-3.0 | 3 | 520 | 1060 | 350 | 25 | 0,6 | 7640161629042 | 810 1420 |

| C 10.1-3.75 | 3,75 | 520 | 1060 | 350 | 25 | 0,6 | 7640161628182 | 810 1421 |

| C 10.1-4.2 | 4,2 | 520 | 1060 | 350 | 25 | 0,6 | 7640161629059 | 810 1422 |

| C 10.1-5.0 | 5 | 520 | 1060 | 350 | 25 | 0,6 | 7640161628199 | 810 1423 |

| C 10.1-6.0 | 6 | 520 | 1060 | 350 | 25 | 0,6 | 7640161628205 | 810 1424 |

T = device depth

Precise pressure maintenance ± 0.1 bar. 2 compressors. Manifold with two bypass valves and safety valve. Intermittent operation, depends on the load.

| A type | PS[bar] | B | H | T | m[kg] | Pel[kW] | EAN | № products |

|---|---|---|---|---|---|---|---|---|

| C 10.2-3.0 | 3 | 520 | 1060 | 350 | 38 | 1,2 | 7640161629066 | 810 1460 |

| C 10.2-3.75 | 3,75 | 520 | 1060 | 350 | 38 | 1,2 | 7640161628236 | 810 1461 |

| C 10.2-4.2 | 4,2 | 520 | 1060 | 350 | 38 | 1,2 | 7640161629073 | 810 1462 |

| C 10.2-5.0 | 5 | 520 | 1060 | 350 | 38 | 1,2 | 7640161628243 | 810 1463 |

| C 10.2-6.0 | 6 | 520 | 1060 | 350 | 38 | 1,2 | 7640161628250 | 810 1464 |

T = device depth

Precise pressure maintenance ± 0.1 bar. 1 compressor. Manifold with two bypass valves and safety valve. Intermittent operation, depends on the load.

| A type | PS[bar] | B | H | T | m[kg] | Pel[kW] | EAN | № products |

|---|---|---|---|---|---|---|---|---|

| C 15.1-6.0 | 6 | 520 | 1060 | 350 | 50 | 1,3 | 7640161628212 | 810 1434 |

| C 15.1-10.0 | 10 | 520 | 1060 | 350 | 50 | 1,3 | 7640161628229 | 810 1435 |

T = device depth

Precise pressure maintenance ± 0.1 bar. 2 compressors. Manifold with two bypass valves and safety valve. Intermittent operation, depends on the load.

| A type | PS[bar] | B | H | T | m[kg] | Pel[kW] | EAN | № products |

|---|---|---|---|---|---|---|---|---|

| C 15.2-6.0 | 6 | 520 | 1060 | 350 | 88 | 2,6 | 7640161628267 | 810 1474 |

| C 15.2-10.0 | 10 | 520 | 1060 | 350 | 88 | 2,6 | 7640161628274 | 810 1475 |

T = device depth

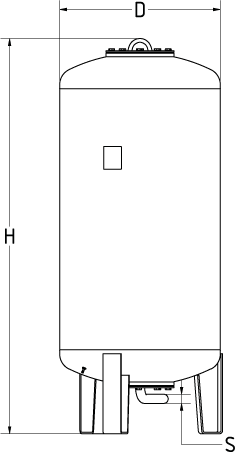

Primary tank. Measuring foot for level measurement. The kit includes a flexible connector for connection on the water side, a shut-off valve for quick emptying of the tank.

| A type | VN[l] | D | H* | HT*** | m[kg] | S | Sw | EAN | № products |

|---|---|---|---|---|---|---|---|---|---|

| 6 bar (PS) | |||||||||

| CU 200.6 | 200 | 500 | 1340 | 1565 | 34 | Rp1 | G3/4 | 7640148630771 | 712 1000 |

| CU 300.6 | 300 | 560 | 1469 | 1690 | 40 | Rp1 | G3/4 | 7640148630788 | 712 1001 |

| CU 400.6 | 400 | 620 | 1532 | 1760 | 58 | Rp1 | G3/4 | 7640148630795 | 712 1002 |

| CU 500.6 | 500 | 680 | 1627 | 1858 | 67 | Rp1 | G3/4 | 7640148630801 | 712 1003 |

| CU 600.6 | 600 | 740 | 1638 | 1873 | 80 | Rp1 | G3/4 | 7640148630818 | 712 1004 |

| CU 800.6 | 800 | 740 | 2132 | 2360 | 98 | Rp1 | G3/4 | 7640148630825 | 712 1005 |

VN = Nominal volume

Secondary tank. The kit includes a flexible connection for the water side connection, a shut-off valve for quick emptying of the tank, and a mounting kit for connecting the tanks on the air side.

| A type | VN[l] | D | H** | HT*** | m[kg] | S | Sw | EAN | № products |

|---|---|---|---|---|---|---|---|---|---|

| 6 bar (PS) | |||||||||

| CU 200.6 E | 200 | 500 | 1340 | 1565 | 33 | Rp1 | G3/4 | 7640148630832 | 712 2000 |

| CU 300.6 E | 300 | 560 | 1469 | 1690 | 39 | Rp1 | G3/4 | 7640148630849 | 712 2001 |

| CU 400.6 E | 400 | 620 | 1532 | 1760 | 57 | Rp1 | G3/4 | 7640148630856 | 712 2002 |

| CU 500.6 E | 500 | 680 | 1627 | 1858 | 66 | Rp1 | G3/4 | 7640148630863 | 712 2003 |

| CU 600.6 E | 600 | 740 | 1638 | 1873 | 79 | Rp1 | G3/4 | 7640148630870 | 712 2004 |

| CU 800.6 E | 800 | 740 | 2132 | 2360 | 97 | Rp1 | G3/4 | 7640148630887 | 712 2005 |

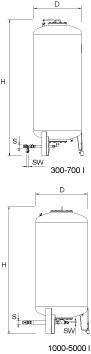

Primary tank. Measuring foot for level measurement. Internal anti-corrosion coating for minimal wear on the camera.

| A type* | VN[l] | D | H** | H*** | m[kg] | S | Sw | EAN | № products |

|---|---|---|---|---|---|---|---|---|---|

| 6 bar (PS) | |||||||||

| CG 300.6 | 300 | 500 | 1823 | 1839 | 140 | Rp1 | G3/4 | 7640148630894 | 712 1006 |

| CG 500.6 | 500 | 650 | 1864 | 1893 | 190 | Rp1 | G3/4 | 7640148630900 | 712 1007 |

| CG 700.6 | 700 | 750 | 1894 | 1931 | 210 | Rp1 | G3/4 | 7640148630917 | 712 1008 |

| CG 1000.6 | 1000 | 850 | 2097 | 2132 | 290 | Rp1 1/2 | G3/4 | 7640148630924 | 712 1009 |

| CG 1500.6 | 1500 | 1016 | 2248 | 2295 | 400 | Rp1 1/2 | G3/4 | 7640148630931 | 712 1010 |

| CG 2000.6 | 2000 | 1016 | 2746 | 2785 | 680 | Rp1 1/2 | G3/4 | 7640148630948 | 712 1015 |

| CG 3000.6 | 3000 | 1300 | 2850 | 2936 | 840 | Rp1 1/2 | G3/4 | 7640148630955 | 712 1012 |

| CG 4000.6 | 4000 | 1300 | 3496 | 3547 | 950 | Rp1 1/2 | G3/4 | 7640148630962 | 712 1013 |

| CG 5000.6 | 5000 | 1300 | 4134 | 4183 | 1050 | Rp1 1/2 | G3/4 | 7640148630979 | 712 1014 |

| 10 bar (PS) | |||||||||

| CG 300.10 | 300 | 500 | 1854 | 1866 | 160 | Rp1 | G3/4 | 7640148631075 | 712 3000 |

| CG 500.10 | 500 | 650 | 1897 | 1921 | 220 | Rp1 | G3/4 | 7640148631082 | 712 3001 |

| CG 700.10 | 700 | 750 | 1928 | 1961 | 250 | Rp1 | G3/4 | 7640148631099 | 712 3002 |

| CG 1000.10 | 1000 | 850 | 2097 | 2132 | 340 | Rp1 1/2 | G3/4 | 7640148631105 | 712 3003 |

| CG 1500.10 | 1500 | 1016 | 2285 | 2331 | 460 | Rp1 1/2 | G3/4 | 7640148631112 | 712 3004 |

| CG 2000.10 | 2000 | 1016 | 2779 | 2819 | 760 | Rp1 1/2 | G3/4 | 7640148631129 | 712 3009 |

| CG 3000.10 | 3000 | 1300 | 2879 | 2942 | 920 | Rp1 1/2 | G3/4 | 7640148631136 | 712 3006 |

| CG 4000.10 | 4000 | 1300 | 3524 | 3576 | 1060 | Rp1 1/2 | G3/4 | 7640148631143 | 712 3007 |

| CG 5000.10 | 5000 | 1300 | 4169 | 4211 | 1180 | Rp1 1/2 | G3/4 | 7640148631150 | 712 3008 |

VN = Nominal volume

| A type* | VN[l] | D | H** | H*** | m[kg] | S | Sw | EAN | № products |

|---|---|---|---|---|---|---|---|---|---|

| 6 bar (PS) | |||||||||

| CG 300.6 E | 300 | 500 | 1823 | 1839 | 140 | Rp1 | G3/4 | 7640148630986 | 712 2006 |

| CG 500.6 E | 500 | 650 | 1864 | 1893 | 190 | Rp1 | G3/4 | 7640148630993 | 712 2007 |

| CG 700.6 E | 700 | 750 | 1894 | 1931 | 210 | Rp1 | G3/4 | 7640148631006 | 712 2008 |

| CG 1000.6 E | 1000 | 850 | 2097 | 2132 | 290 | Rp1 1/2 | G3/4 | 7640148631013 | 712 2009 |

| CG 1500.6 E | 1500 | 1016 | 2248 | 2295 | 400 | Rp1 1/2 | G3/4 | 7640148631020 | 712 2010 |

| CG 2000.6 E | 2000 | 1016 | 2746 | 2785 | 680 | Rp1 1/2 | G3/4 | 7640148631037 | 712 2015 |

| CG 3000.6 E | 3000 | 1300 | 2850 | 2936 | 840 | Rp1 1/2 | G3/4 | 7640148631044 | 712 2012 |

| CG 4000.6 E | 4000 | 1300 | 3496 | 3547 | 950 | Rp1 1/2 | G3/4 | 7640148631051 | 712 2013 |

| CG 5000.6 E | 5000 | 1300 | 4134 | 4183 | 1050 | Rp1 1/2 | G3/4 | 7640148631068 | 712 2014 |

| 10 bar (PS) | |||||||||

| CG 300.10 E | 300 | 500 | 1854 | 1866 | 160 | Rp1 | G3/4 | 7640148631167 | 712 4000 |

| CG 500.10 E | 500 | 650 | 1897 | 1921 | 220 | Rp1 | G3/4 | 7640148631174 | 712 4001 |

| CG 700.10 E | 700 | 750 | 1928 | 1961 | 250 | Rp1 | G3/4 | 7640148631181 | 712 4002 |

| CG 1000.10 E | 1000 | 850 | 2097 | 2132 | 340 | Rp1 1/2 | G3/4 | 7640148631198 | 712 4003 |

| CG 1500.10 E | 1500 | 1016 | 2285 | 2331 | 460 | Rp1 1/2 | G3/4 | 7640148631204 | 712 4004 |

| CG 2000.10 E | 2000 | 1016 | 2779 | 2819 | 760 | Rp1 1/2 | G3/4 | 7640148631211 | 712 4009 |

| CG 3000.10 E | 3000 | 1300 | 2879 | 2942 | 920 | Rp1 1/2 | G3/4 | 7640148631228 | 712 4006 |

| CG 4000.10 E | 4000 | 1300 | 3524 | 3576 | 1060 | Rp1 1/2 | G3/4 | 7640148631235 | 712 4007 |

| CG 5000.10 E | 5000 | 1300 | 4169 | 4211 | 1180 | Rp1 1/2 | G3/4 | 7640148631242 | 712 4008 |

Application area:

Only in conjunction with the TecBox control unit.

See annexes under the technical description - TecBox control unit.

Wednesday:

Non-corrosive and non-toxic media.

Antifreeze up to 50%.

Pressure:

Minimum allowable pressure, PSmin: 0 bar

Maximum allowable pressure, PS: see article numbers

Temperature:

Maximum allowable chamber temperature, TB: 70 ° C

Minimum permissible chamber temperature, TBmin: 5 ° C

According to PED:

Maximum permissible temperature, TS: 120 ° C

Minimum allowable temperature, TSmin: -10 ° C

Material:

Steel. Beryllium color.

Airproof butyl rubber chamber according to EN 13831 and Pneumatex internal standard.

Transport and storage:

In warm and dry places.

Standards:

Manufactured according to PED 2014/68 / EU.

Guarantee:

Compresso CG, CG… E: 5-year warranty for the airtight butyl rubber chamber.

Compresso CU, CU… E: 5-year tank warranty.

We will tell you in detail about our services, types of work and typical projects, calculate the cost and prepare an individual offer!