Mechanism of Action

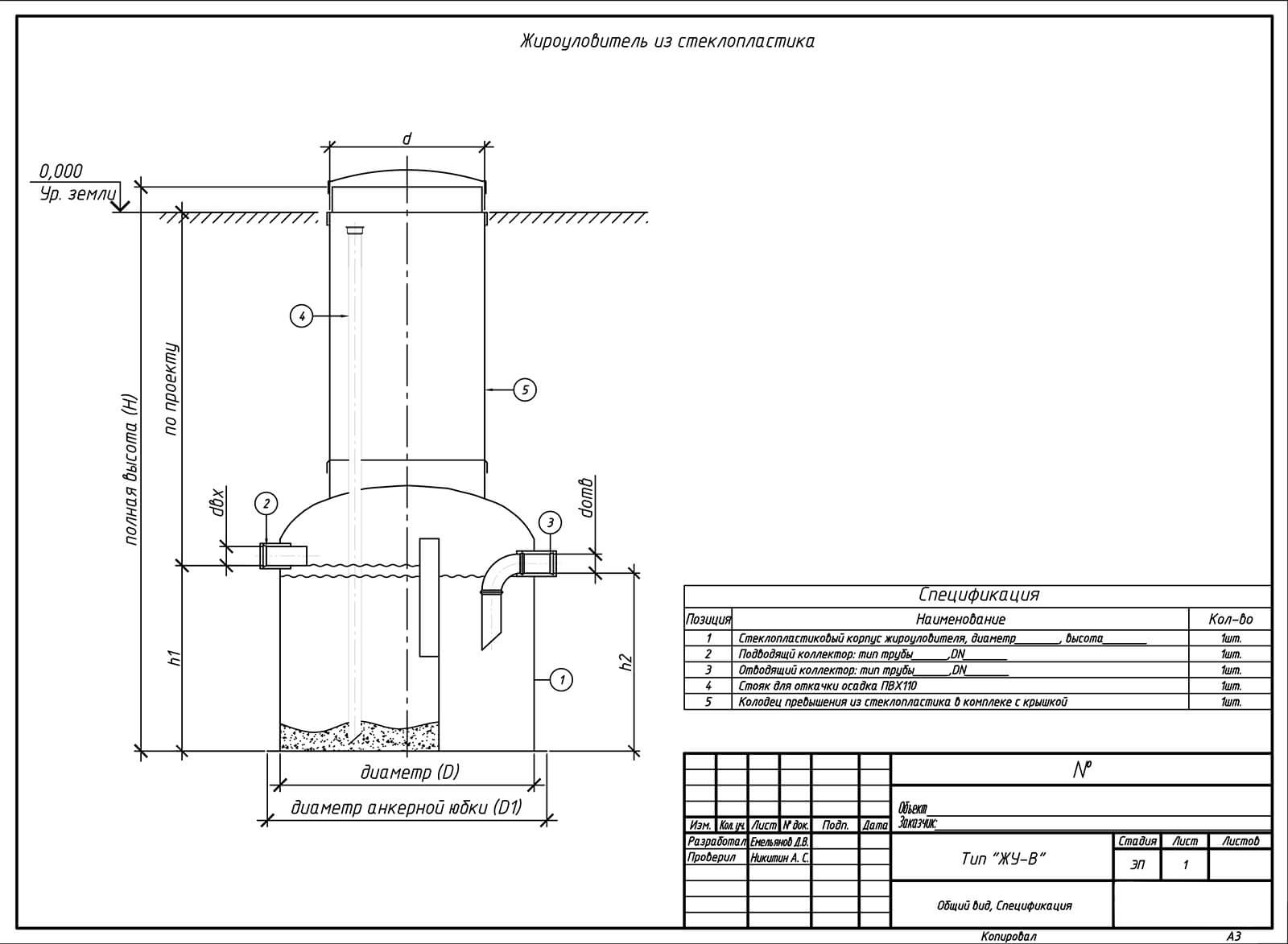

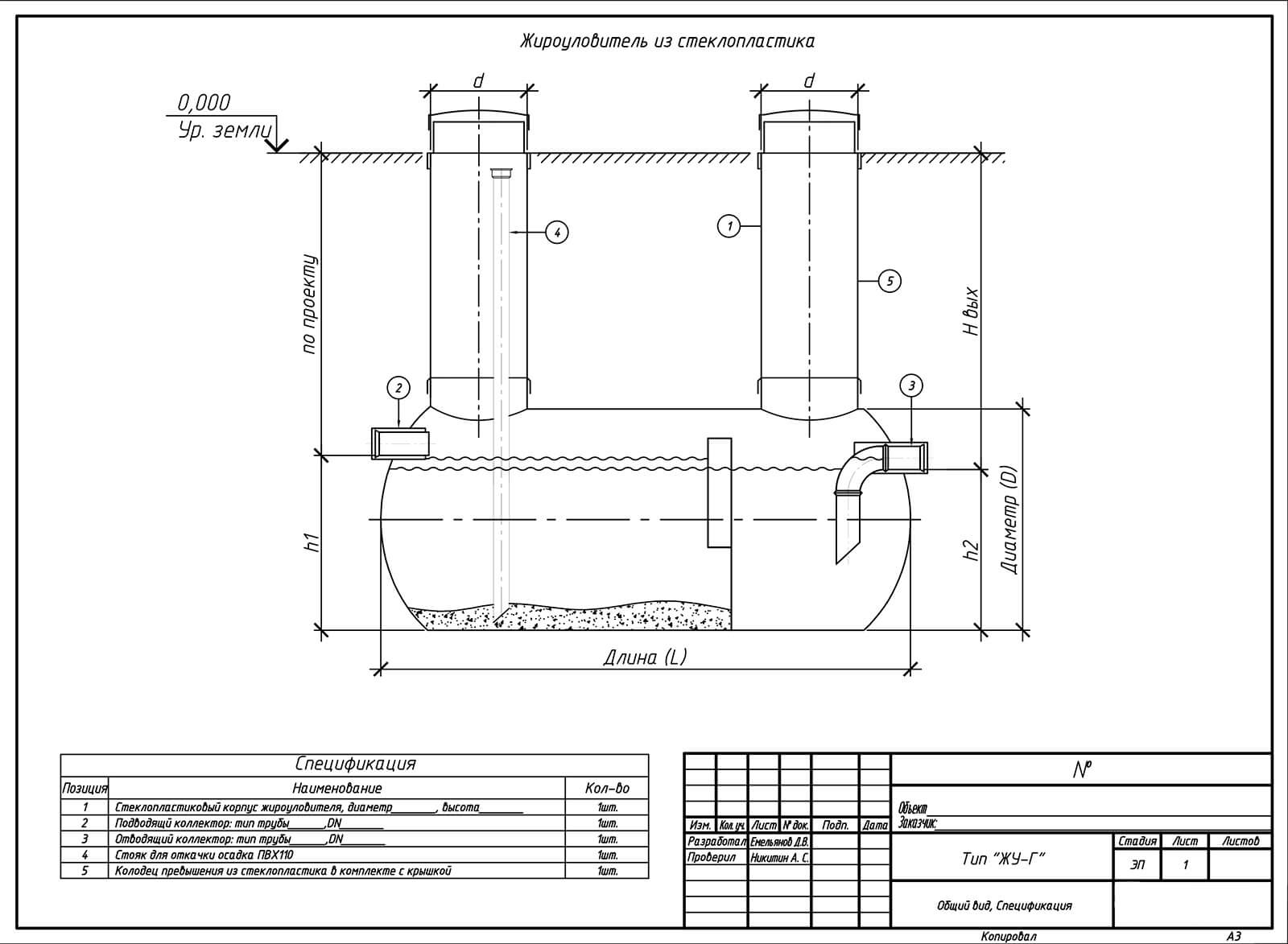

The device`s operation is based on the physical properties of various substances. The purification process is carried out in stages:

- Contaminated wastewater enters the primary compartment

- Flow is slowed and water temperature is reduced by special partitions

- Natural floating of fat fractions due to their lower density

- Transfer of purified liquid to the secondary compartment

- Final filtration stage

- Discharge of purified water into the sewer system

Key advantages

Installing a grease trap provides a number of significant advantages:

- Reliable protection of the sewer system from grease plugs

- Compliance with environmental standards

- Ease of installation and subsequent maintenance

- Efficient elimination of unpleasant odors

- Increasing the service life of the sewer system

- Optimal price-quality ratio

Applications

The equipment is widely used in various fields:

- Cateringof all formats

- Food industryof various sizes

- Food establishmentsfrom small cafes to large restaurants

- Dairy production

- Meat processing plants

- Private households

Device classification

By functional purpose A distinction is made between:

- Home models for individual use

- Industrial systems for large-scale facilities

By purification technology, a distinction is made between:

- Mechanical units with natural fat separation

- Biofilters based on microbiological processes

- Chemical systems using special reagents

Equipment selection factors

When selecting the optimal option, the following should be taken into account:

- Water consumption intensity

- Sewage system parameters

- Dimensions of the room for Installation

- Wastewater specifics

- Number of connected water points

- Material preferences

Installation rules

Placement recommendations:

- Domestic models are installed under the sink or within a 5-meter radius.

- Industrial models require a separate room or basement.

- Optimum temperature range: from +5 to +40°C.

- Mandatory adherence to the preventive cleaning schedule.

Final conclusions

Grease trap equipment is a critical infrastructure element in areas with high fat content in wastewater. Proper model selection, combined with regular maintenance, ensures stable and efficient system operation over a long period.