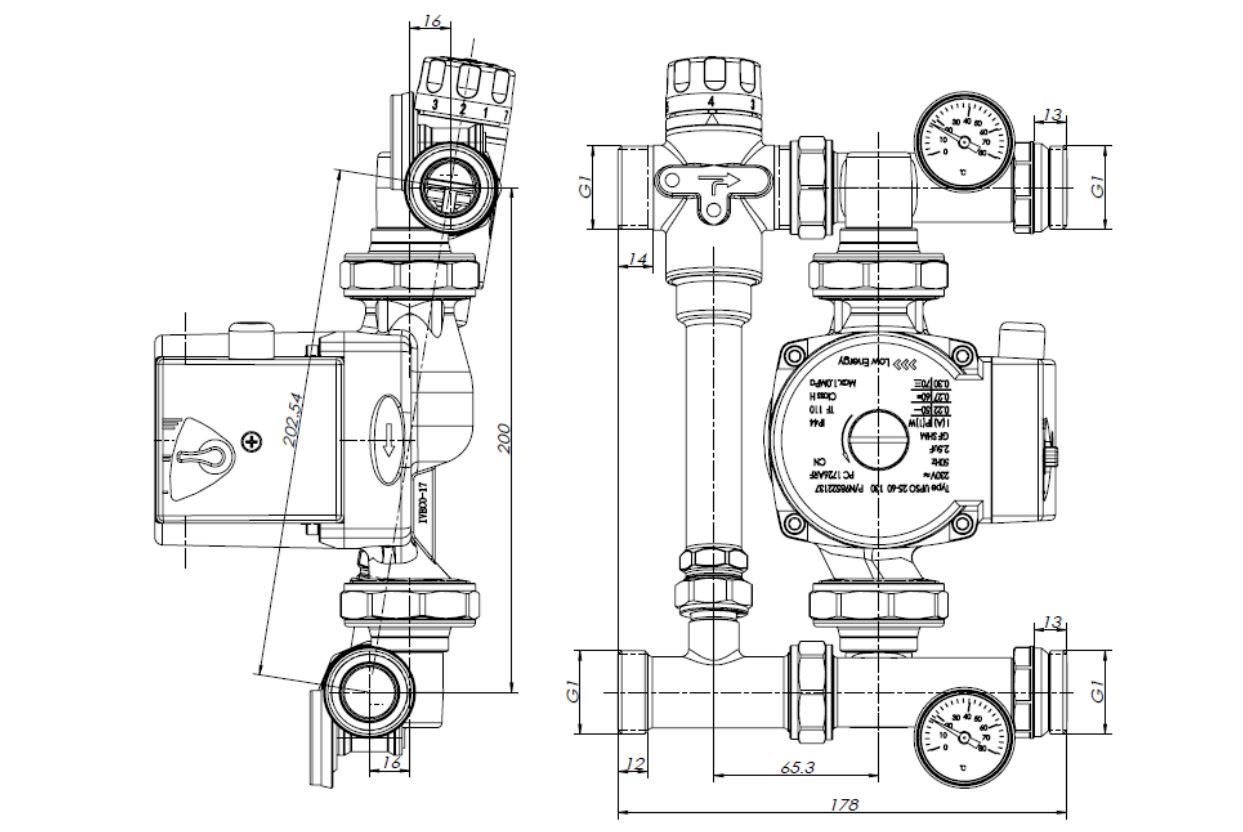

Article: MU.501.06

| # | Feature | Value |

|---|---|---|

| 1 | Maximum operating temperature of the medium at the inlet, °С | 85 |

| 2 | Pressure drop between cold and hot water inlet (high to low pressure ratio) | ≤ 2: 1 |

| 3 | Nominal pressure PN, bar | 10 |

| 4 | Temperature setting range, °С | 30-60 |

| 5 | Factory setting, °С | 45 |

| 6 | Connection thread size | 1 " |

| 7 | Maximum thermal power, kW | 22.5 |

| 8 | Installation length of the installed pump, mm | 130 |

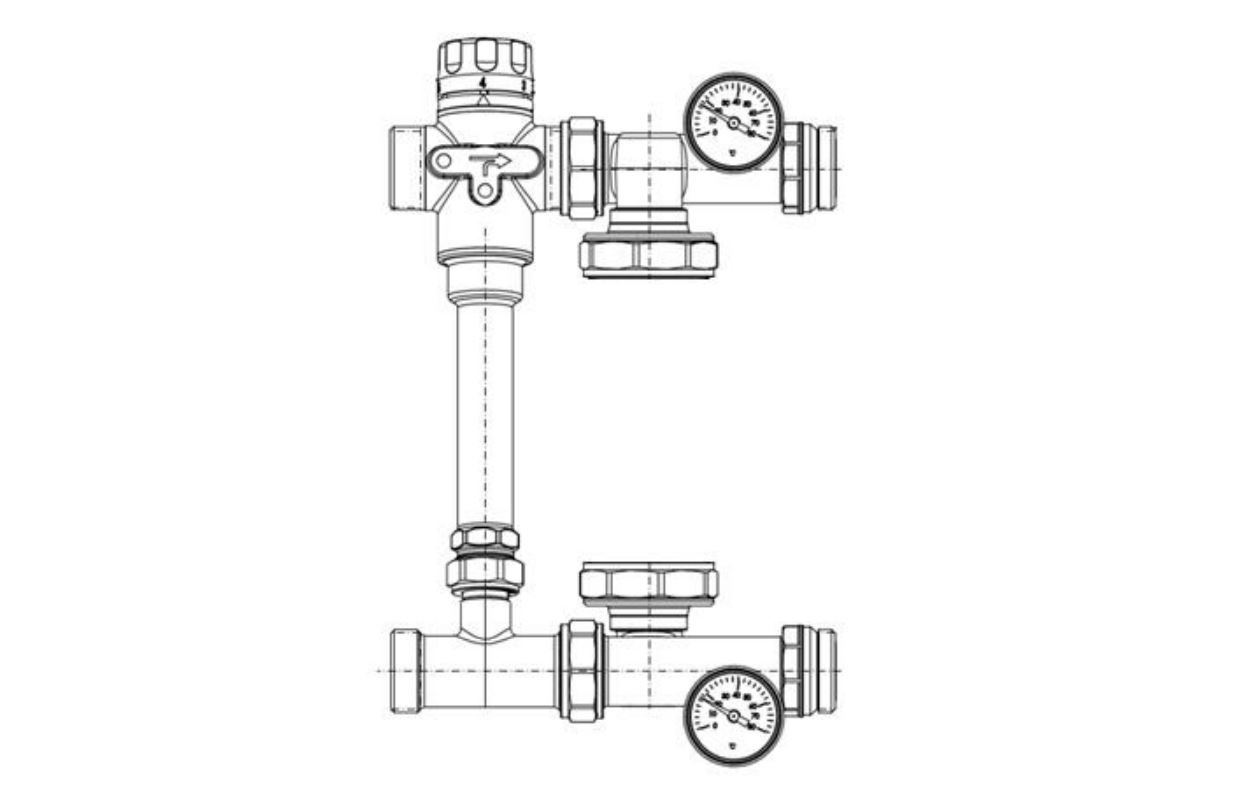

The products must be operated at the pressure and temperature specified in the table of technical characteristics. Freezing of the working medium inside the valve is not allowed. It is recommended that group maintenance be carried out every 6 months with a qualified installer.

Instructions for replacing the circulation pump:

Note: in case of failure of the electrical part of the pump (stator), it is recommended to replace only it, and leave the hydraulic housing.

| # | Part name | Material | Material grade according to norms | |

|---|---|---|---|---|

| RF | EN | |||

| 1 | Corpus | Brass | ЛС-59-2 | CW617N |

| 2 | Bypass | Brass | ЛС-59-2 | CW617N |

| 3 | Rokyat | Polymer | Polyamide | PA6 + GF |

| 4 | Seals | Elastomer | Rubber | ERDM |

| 5 | Pump Nut | Brass | ЛС-59-2 | CW617N |

We will tell you in detail about our services, types of work and typical projects, calculate the cost and prepare an individual offer!