| Nominal diameter (DN, mm): | 50, 65, 80, 100, 125, 150, 200, 250, 300, 350, 400, 500, 600, 700, 800, 900, 1000 |

| Nominal pressure (Pwork, PN): | 25 bar |

| Working environment temperature: | up to +150°C |

Bellows compensating device with heat and waterproof bellows and a sleeve in a polyethylene sheath with factory-applied PPU insulation of the branch pipes applied under it.

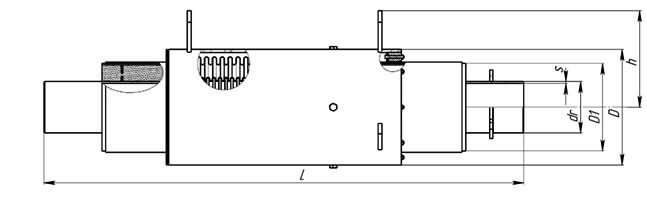

Bellows compensating device with heat- and water-insulated bellows and a sleeve in a polyethylene sheath with factory-applied PPU pipe insulation applied under it, equipped with a heat- and water-insulated multilayer stainless steel bellows, welded pipes with factory insulation, sleeve in a polyethylene sheath for PU foam insulation, stuffing box for waterproofing, a protective cover, guides to prevent torsional rotation and a washer for additional installation of the pre-stretching mechanism. Lifting and pre-stretching lugs are provided in the product. It is possible to manufacture with additional thermal insulation of the bellows and SODK conductors.

Specifications are shown in the table 1.

table 1

| Callout | Nominal diameter | Nominal pressure | Dimensions | Axial compensating ability | Estimated weight | Calculated stiffness | Estimated effective area | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DN | РN | dr | s | D | D1 | h | L | Δ | ±λ | Сλ | Sэф | |||

|

мм mm |

Бар bar |

мм mm |

мм mm |

мм mm |

мм mm |

мм mm |

мм mm |

мм mm |

мм mm |

кг kg |

Н/мм N/mm |

см2 cm2 |

||

| СКУ.ППУ/ТПЭ 50-25-70 | 50 | 25 | 57 | 3,5 | 245 | 127 | 220 | 1199 | 70 | 35 | 52 | 493,38 | 60,67 | |

| СКУ.ППУ/ТПЭ 65-25-70 | 65 | 25 | 76 | 4,0 | 245 | 142 | 220 | 1199 | 70 | 35 | 59 | 493,98 | 60,67 | |

| СКУ.ППУ/ТПЭ 80-25-70 | 80 | 25 | 89 | 4,0 | 245 | 164 | 220 | 1209 | 70 | 35 | 63 | 436,06 | 83,47 | |

| СКУ.ППУ/ТПЭ 100-25-100 | 100 | 25 | 108 | 4,0 | 299 | 182 | 250 | 1220 | 100 | 50 | 85 | 494,67 | 118,05 | |

| СКУ.ППУ/ТПЭ 125-25-100 | 125 | 25 | 133 | 5,0 | 299 | 227 | 250 | 1242 | 100 | 50 | 96 | 599,12 | 155,04 | |

| СКУ.ППУ/ТПЭ 150-25-100 | 150 | 25 | 159 | 5,0 | 377 | 252 | 288,5 | 1256 | 100 | 50 | 126 | 562,83 | 238,06 | |

| СКУ.ППУ/ТПЭ 200-25-160 | 200 | 25 | 219 | 8,0 | 426 | 317 | 312,5 | 1482 | 160 | 80 | 218 | 678,03 | 459,16 | |

| СКУ.ППУ/ТПЭ 250-25-160 | 250 | 25 | 273 | 8,0 | 480 | 402 | 340 | 1711 | 160 | 80 | 272 | 675,61 | 686,23 | |

| СКУ.ППУ/ТПЭ 300-25-180 | 300 | 25 | 325 | 8,0 | 530 | 452 | 365 | 1732 | 180 | 90 | 331 | 818,86 | 963,16 | |

| СКУ.ППУ/ТПЭ 400-25-190 | 400 | 25 | 426 | 9,0 | 650 | 562 | 425 | 1808 | 190 | 95 | 491 | 1163,59 | 1630,98 | |

| СКУ.ППУ/ТПЭ 500-25-200 | 500 | 25 | 530 | 8,0 | 820 | 712 | 510 | 1842 | 200 | 100 | 596 | 1335,56 | 2468,29 | |

| СКУ.ППУ/ТПЭ 600-25-200 | 600 | 25 | 630 | 10,0 | 950 | 802 | 575 | 1863 | 200 | 100 | 985 | 1632,91 | 3425,34 | |

| СКУ.ППУ/ТПЭ 700-25-210 | 700 | 25 | 720 | 10,0 | 1060 | 902 | 630 | 1904 | 210 | 105 | 1135 | 1812,19 | 4488,83 | |

| СКУ.ППУ/ТПЭ 800-25-210 | 800 | 25 | 820 | 12,0 | 1160 | 1002 | 680 | 1913 | 210 | 105 | 1362 | 1914,61 | 5780,47 | |

| СКУ.ППУ/ТПЭ 1000-25-220 | 1000 | 25 | 1020 | 14,0 | 1360 | 1202 | 780 | 1942 | 220 | 110 | 1775 | 2591,27 | 8841,39 | |

Note:

1. Additional thermal insulation of the bellows is possible.

2. Variants with other technical parameters are possible.

3. The product can be completed with a pre-stretching mechanism in the amount of 1 piece.

4. The estimated weight of the expansion joint may differ from the actual weight.

5. Additional installation of SODK (operational remote control system) is possible.

6. It is possible to manufacture type 1 and type 2 thermal insulation (according to GOST 30732).

7. It is possible to manufacture an expansion joint in a galvanized sheath (when manufacturing an expansion joint in a galvanized sheath, the product will not have lifting and pre-stretching eyes).

8. The appearance of the structure may vary.

We will tell you in detail about our services, types of work and typical projects, calculate the cost and prepare an individual offer!