| Nominal diameter (DN, mm): | 50, 65, 80, 100, 125, 150, 200, 250, 300, 350, 400, 500, 600, 700, 800, 900, 1000, 1200. |

| Nominal pressure (Pwork, PN): | 25 bar |

| Working environment temperature: | up to +250°C |

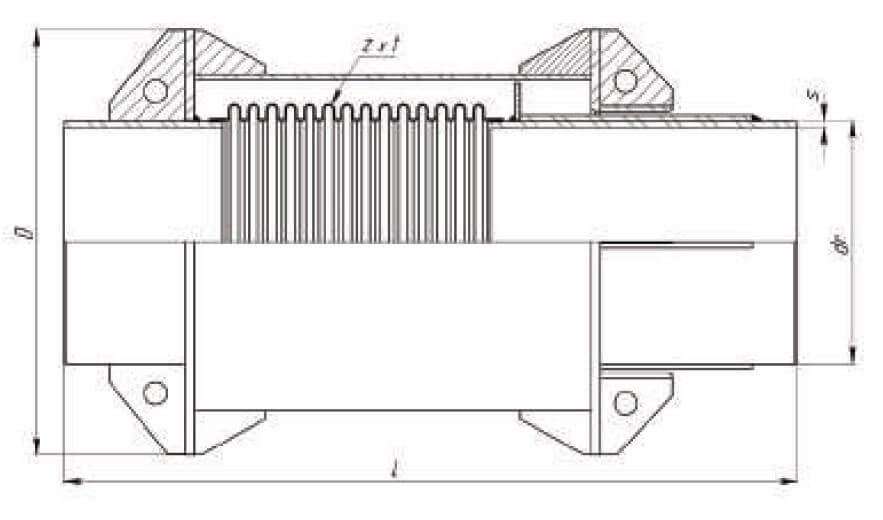

CSR.UK – axial bellows expansion joints with a reinforced welded casing with a nominal pressure of PN 25 Bar (25 kgf / cm2) as standard.

Axial bellows expansion joints with a reinforced protective casing are used to compensate for axial movements arising from the thermal expansion of the heating network pipeline inside premises, during above-ground laying, in chambers, through or non-through channels, tunnels. The reinforced casing of the expansion joint serves as a guide, reliably protects the bellows from excessive stretching and bending moments.

At the request of the Customer, an observation window can be included in the design for the possibility of monitoring the condition of the bellows surface during the entire period of operation. It is allowed to apply thermal insulation on the casing of the compensator after their installation in the heat pipe simultaneously with the thermal insulation of the heat pipe.

This type of expansion joints is recommended for replacing stuffing box expansion joints when installed in existing heat chambers.

Цель применения:

Operating conditions:

Working medium: steam, water.

Design Features

Technical characteristics of axial bellows expansion joints with a reinforced welded casing (KSO.UK) with a nominal pressure of PN 25 Bar (25 kgf / cm2) as standard

Material execution :

| Bellow: | stainless steel AISI 321 (analogue 08 * 18H10T, 12 * 18H10T) & nbsp; |

| Connecting part: | stainless steel AISI 321 (analogue 08 * 18H10T, 12 * 18H10T), carbon steel: steel 10, steel 20, 17GS, 17G1S, 09G2, 09G2S & nbsp; |

| Reinforced outer casing: | stainless steel AISI 321 (analogue 08 * 18H10T, 12 * 18H10T), carbon steel: steel 20, st.10, st.3, 09G2S & nbsp; |

| Restriction and safety fittings : | stainless steel AISI 321 (analogue 08 * 18H10T, 12 * 18H10T), carbon steel: st.3, 09G2S & nbsp; |

Technical characteristics of KSO.UK:

| Callout | Nominal diameter | Nominal pressure | Dimensions | Axial compensating ability | Calculated weight | Calculated stiffness | Calculated effective area | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| DN | PN | dr | s | D | L | ? | ±? | С? | Sэф | ||

|

мм mm |

Бар bar |

мм mm |

мм mm |

мм mm |

мм mm |

мм mm |

мм mm |

кг kg |

Н/мм N/mm |

см2 cm2 |

|

| КСО.УК 65-25-70 | 65 | 25 | 76 | 4,0 | 235 | 844 | 70 | 35 | 21,45 | 376,44 | 60,81 |

| КСО.УК 80-25-70 | 80 | 25 | 89 | 4,0 | 260 | 854 | 70 | 35 | 27 | 302,93 | 83,47 |

| КСО.УК 100-25-100 | 100 | 25 | 108 | 4,0 | 320 | 875 | 100 | 50 | 37,56 | 268,62 | 118,05 |

| КСО.УК 125-25-100 | 125 | 25 | 133 | 5,0 | 320 | 897 | 100 | 50 | 42,4 | 373,92 | 155,92 |

| КСО.УК 150-25-100 | 150 | 25 | 159 | 5,0 | 375 | 925 | 100 | 50 | 53,2 | 233,61 | 237,24 |

| КСО.УК 200-25-160 | 200 | 25 | 219 | 8,0 | 425 | 1011 | 160 | 80 | 80,3 | 458,95 | 459,16 |

| КСО.УК 250-25-160 | 250 | 25 | 273 | 8,0 | 477 | 823 | 160 | 80 | 98,96 | 579,07 | 687,20 |

| КСО.УК 300-25-180 | 300 | 25 | 325 | 8,0 | 526 | 854 | 180 | 90 | 117,57 | 816,96 | 964,31 |

| КСО.УК 350-25-180 | 350 | 25 | 377 | 7,0 | 630 | 880 | 180 | 90 | 164,9 | 632,75 | 1239,73 |

| КСО.УК 400-25-190 | 400 | 25 | 426 | 9,0 | 630 | 910 | 190 | 95 | 181,5 | 847,78 | 1623,83 |

| КСО.УК 500-25-200 | 500 | 25 | 530 | 8,0 | 820 | 934 | 200 | 100 | 278,84 | 1584,77 | 2471,81 |

| КСО.УК 600-25-200 | 600 | 25 | 630 | 10,0 | 920 | 955 | 200 | 100 | 306 | 1729,27 | 3437,80 |

| КСО.УК 700-25-210 | 700 | 25 | 720 | 10,0 | 1020 | 962 | 210 | 105 | 392,5 | 1494,54 | 4488,83 |

| КСО.УК 800-25-210 | 800 | 25 | 820 | 12,0 | 1120 | 995 | 210 | 105 | 478 | 2282,35 | 5787,21 |

| КСО.УК 900-25-210 | 900 | 25 | 920 | 14,0 | 1320 | 971 | 210 | 105 | 696,73 | 2315,84 | 7244,26 |

| КСО.УК 1000-25-220 | 1000 | 25 | 1020 | 14,0 | 1320 | 1006 | 220 | 110 | 663,5 | 2544,27 | 8844,73 |

| КСО.УК 1200-25-220 | 1200 | 25 | 1220 | 16,0 | 1520 | 1006 | 220 | 110 | 900,73 | 2934,23 | 12546,29 |

Note:

1. Versions with an inner shield are possible.

2. & nbsp; It is possible to manufacture expansion joints with a flange connection.

3. The estimated weight of the expansion joint may differ from the actual weight.

4. The appearance of the structure may vary.

5. It is possible to manufacture according to the technical requirements of the customer.

We will tell you in detail about our services, types of work and typical projects, calculate the cost and prepare an individual offer!