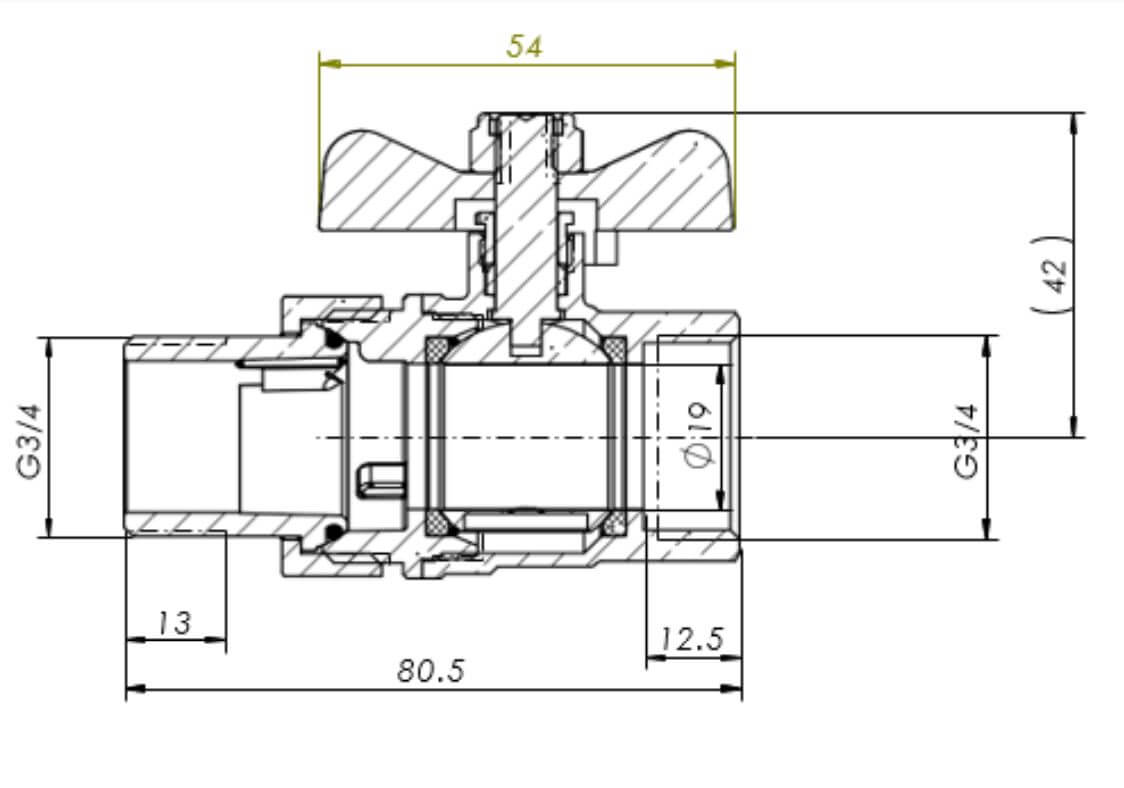

| # | Feature | Value |

|---|---|---|

| 1 | Maximum temperature of the working environment, ° С | 150 |

| 2 | Nominal maximum pressure, bar | 40 |

| 3 | Throughput, m3 / hour | ½ "- 19.8 ¾" - 21.22 1 "- 49.7 1 * 1/4" - 76.13 |

| 4 | Valve tightness class | "A" |

| 5 | Maintainability | Yes |

| 6 | Transition Characteristic | Full |

| 7 | Mean time between failures, cycles | 25000 |

| 8 | Average total life, cycles | 55000 |

Full bore ball valves MVI of the BV.71 ... series are shut-off valves and are not intended for flow control. They perform the function of quickly shutting off the flow on pipelines for domestic use of hot and cold water supply systems, heating. Do not create resistance to the flow Use of ball valves as control valves is prohibited. A feature of ball valves of the H2O series is the use of special brass with a low lead content in the manufacture of the body – CW510L. Plus a special design of the ball valve – with holes. This solution prevents the formation of Legionella bacteria and protects the body from bursting when the working fluid freezes in the middle of the valve.

- Legionella Pneumophila - bacterium-causative agent of LEGIONELLOSIS (Legionnaires` disease, Pittsburgh pneumonia, Pontian fever) - an acute infectious disease characterized by fever, expressed general intoxication, severe course, damage to the lungs, central nervous system, digestive organs; - Studies have shown that one of the causes of sporadic cases of legionellosis is the presence of Legionella bacteria in the domestic water supply system;

- This often happens when there are dead zones in the fittings. Therefore, ball valves have holes in the valve ball for flushing stagnant zones. In this case, the likelihood of the appearance of Legionellosis bacteria is reduced to zero.

- There are holes in the bottom of the valve ball of the H2O series valves;

- The perforation of the ball helps to equalize the pressure in the body cavity and in the pipeline, and when the valve is open, the pressure of frozen water is removed through the holes in the ball, which destroys the valve.

Valves must be operated at pressure and temperature, set out in the table of technical characteristics. It is strictly forbidden to allow the working environment to freeze. inside the tap. When draining the system in winter, the valve must be left half-open so that the work environment does not remain in cavities behind the shutter. Ball valves are operated simultaneously with only one maximum parameter (pressure or temperature). Use product with simultaneous parameters is prohibited.

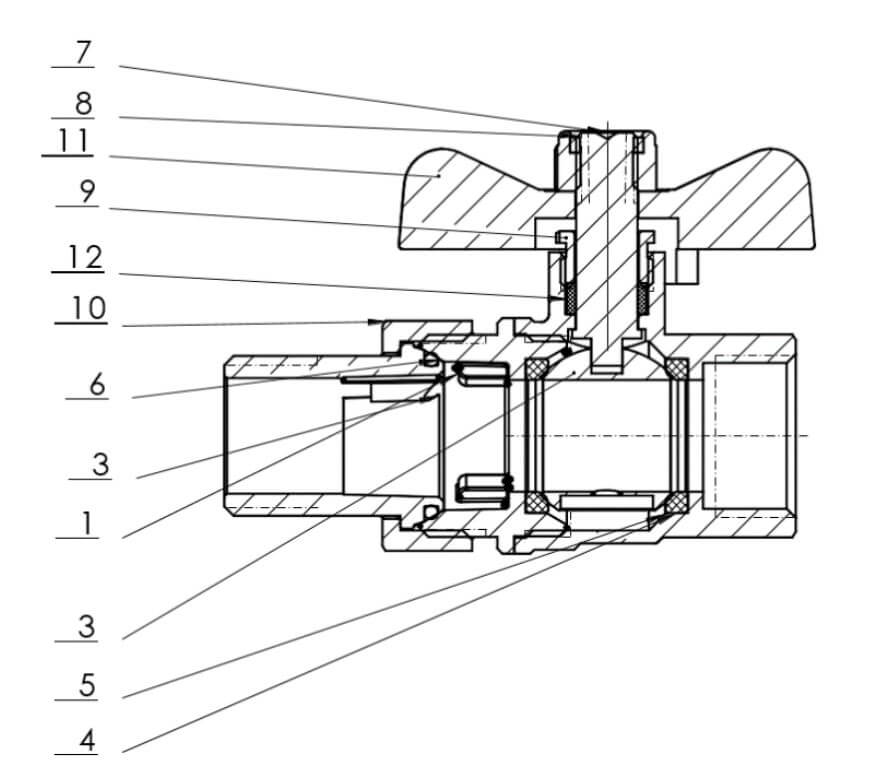

| # | Part name | Material | Material grade according to norms | |

|---|---|---|---|---|

| RF | EN | |||

| 1 | Small body | Brass | Brass | CW510L |

| 2 | Ball Valve | Brass | Brass | CW510L |

| 3 | Halftone fitting | Brass | Brass | CW510L |

| 4 | Seat Ring | Teflon | Teflon | PTFE |

| 5 | Semi-hull, large | Brass | Brass | CW510L |

| 6 | Nipple seal | Elastomer | Rubber | EPDM |

| 7 | Nut | Stainless steel | 08Х18Н10 | AISI304 |

| 8 | Stock | Brass | Brass | CW510L |

| 9 | Locking nut | Brass | Brass | CW510L |

| 10 | Union nut | Brass | ЛС-59 | CW617N |

| 11 | Butterfly | Aluminum | Aluminum | Al-46100 |

| 11 | Lever | Steel | Steel | Q235 |

| 12 | Stem Seal | Teflon | Teflon | PTFE |

We will tell you in detail about our services, types of work and typical projects, calculate the cost and prepare an individual offer!