KEY FEATURES

High accuracy for all settings

Ensures accurate balancing.

Lever

The readable handle provides accurate and easy balancing. A shut-off function makes maintenance easier.

Self-sealing test points

They guarantee simplicity and accuracy of balancing.

AMETAL® alloy

Zinc loss resistant alloy for long valve life and reduced risk of leakage.

SPECIFICATIONS

Application area:

Heating and cooling systems

Water supply systems

Function:

Balancing

Presetting

Measurement

Closing

Drainage (depending on valve type)

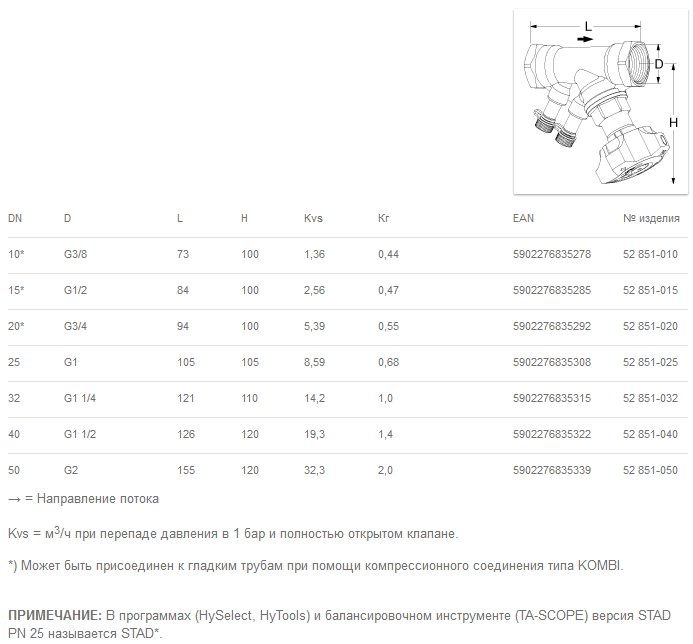

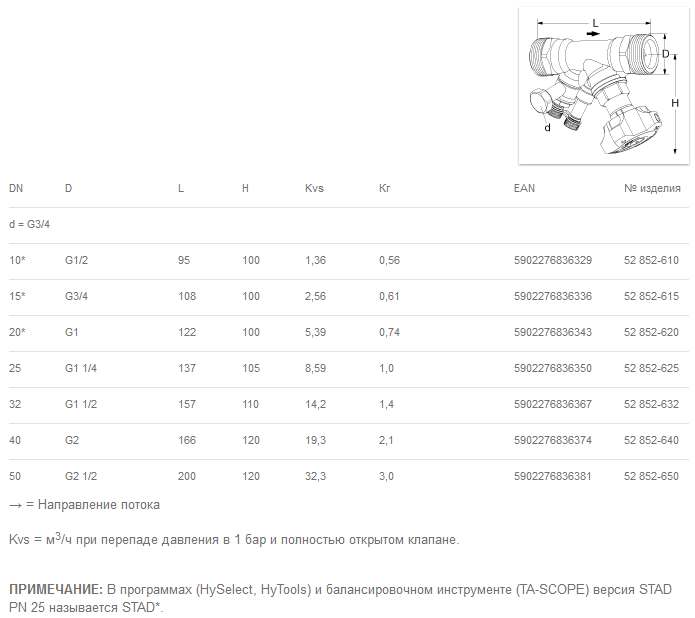

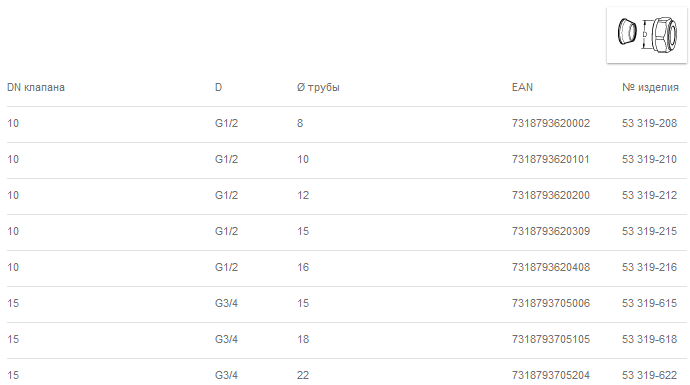

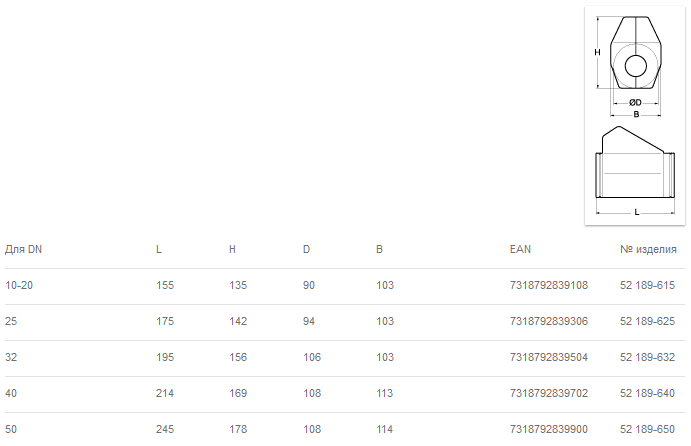

Size range:

DN 10-50

Nominal pressure:

PN 25

Temperature:

Max. working temperature: 120 ° C

(short-term 150 ° C)

For higher temperatures (max. 150 ° C), see STAD-C.

Min. working temperature: -20 ° C

Wednesday:

Water and neutral liquids, water-glycol mixture (0-57%).

Material:

Measuring points: AMETAL®

Seals: EPDM

Covers: Polyamide and TPE

Drainage: AMETAL®

Seal: EPDM

Spacers: Aramid fibers

AMETAL® is a zinc loss resistant copper alloy developed by IMI Hydronic Engineering.

Marking:

Body: IMI, TA, PN 25/400 WWP, DN and inch size. DN 50 also CE.

Orange / gray handle: TA, STAD * and DN.

Compound:

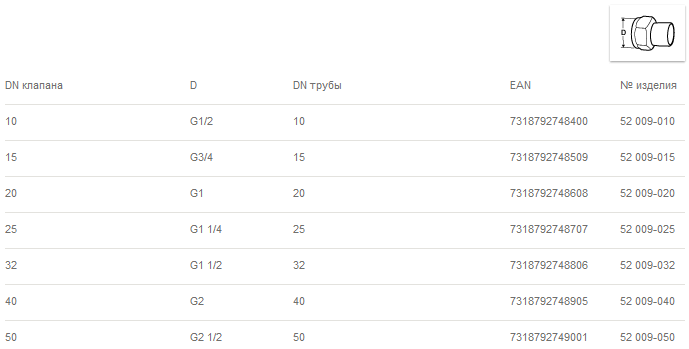

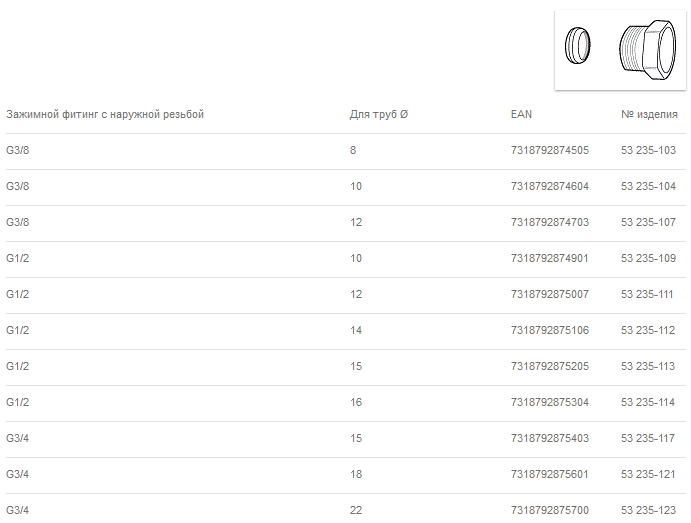

- Internal thread according to ISO 228. Thread length according to ISO 7/1.

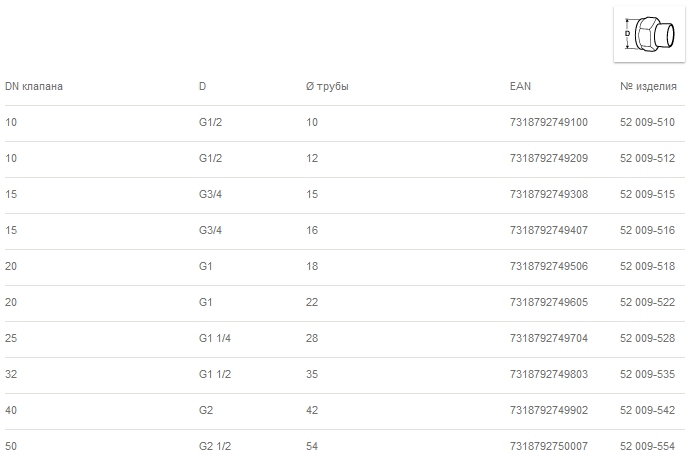

- External thread according to ISO 228. Thread length according to DIN 3546.

Approvals:

WRAS

Can be installed without draining the system. AMETAL® / Stainless steel / EPDM

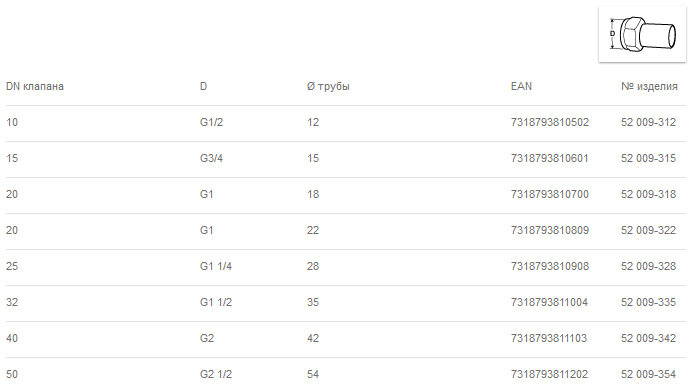

Max. 100°C Brass / AMETAL® Use support sleeves. For more information see the FPL connection catalog.

Max. 100°C (For more information, see the catalog on the KOMBI connection.)

For heating and cooling systems. Polyurethane without CFC (CFC-free polyurethane). Covered with gray PVC. You can find detailed information on insulation in the Insulation catalog.

We will tell you in detail about our services, types of work and typical projects, calculate the cost and prepare an individual offer!